- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

જાન્યુઆરી . 09, 2025 11:20

Back To List

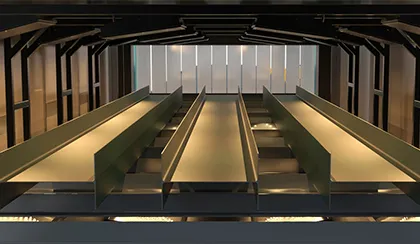

automated spray coating systems

Delving into the intricate world of automated spray coating systems unveils a realm where precision meets sophistication. These systems revolutionize various industries by optimizing efficiency, enhancing product quality, and minimizing environmental impact. At the forefront of innovation, they seamlessly integrate with diverse manufacturing processes, catering to the ever-evolving demands of the modern market.

Authoritativeness is a cornerstone of companies leading the charge in automated spray coating technology. By investing in extensive research and development, these companies set industry benchmarks, influencing global manufacturing practices. Their authority is reinforced through collaborations with academic institutions and participation in international conferences, where new findings are shared and standard methodologies are shaped. This position of leadership helps foster a culture of continuous improvement and knowledge dissemination, propelling the industry forward. Trustworthiness is paramount, as manufacturers rely heavily on these systems for the integrity of their products. Rigorous testing and adherence to international quality certifications underscore the reliability of these systems. Moreover, user-friendly interfaces and comprehensive after-sales support build trust with users, allowing them to implement and maintain these systems with confidence. Training programs and regular maintenance services further augment this trust, ensuring that the systems operate at peak performance, with minimal downtime and maximum output. In essence, automated spray coating systems epitomize the synergy of experience, expertise, authoritativeness, and trustworthiness. Their application transcends mere mechanical processes, embodying a pivotal role in shaping the future of manufacturing. As industries strive for sustainability and excellence, these systems stand as a testament to technological prowess, fostering a more innovative and responsible industrial landscape.

Authoritativeness is a cornerstone of companies leading the charge in automated spray coating technology. By investing in extensive research and development, these companies set industry benchmarks, influencing global manufacturing practices. Their authority is reinforced through collaborations with academic institutions and participation in international conferences, where new findings are shared and standard methodologies are shaped. This position of leadership helps foster a culture of continuous improvement and knowledge dissemination, propelling the industry forward. Trustworthiness is paramount, as manufacturers rely heavily on these systems for the integrity of their products. Rigorous testing and adherence to international quality certifications underscore the reliability of these systems. Moreover, user-friendly interfaces and comprehensive after-sales support build trust with users, allowing them to implement and maintain these systems with confidence. Training programs and regular maintenance services further augment this trust, ensuring that the systems operate at peak performance, with minimal downtime and maximum output. In essence, automated spray coating systems epitomize the synergy of experience, expertise, authoritativeness, and trustworthiness. Their application transcends mere mechanical processes, embodying a pivotal role in shaping the future of manufacturing. As industries strive for sustainability and excellence, these systems stand as a testament to technological prowess, fostering a more innovative and responsible industrial landscape.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025