- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

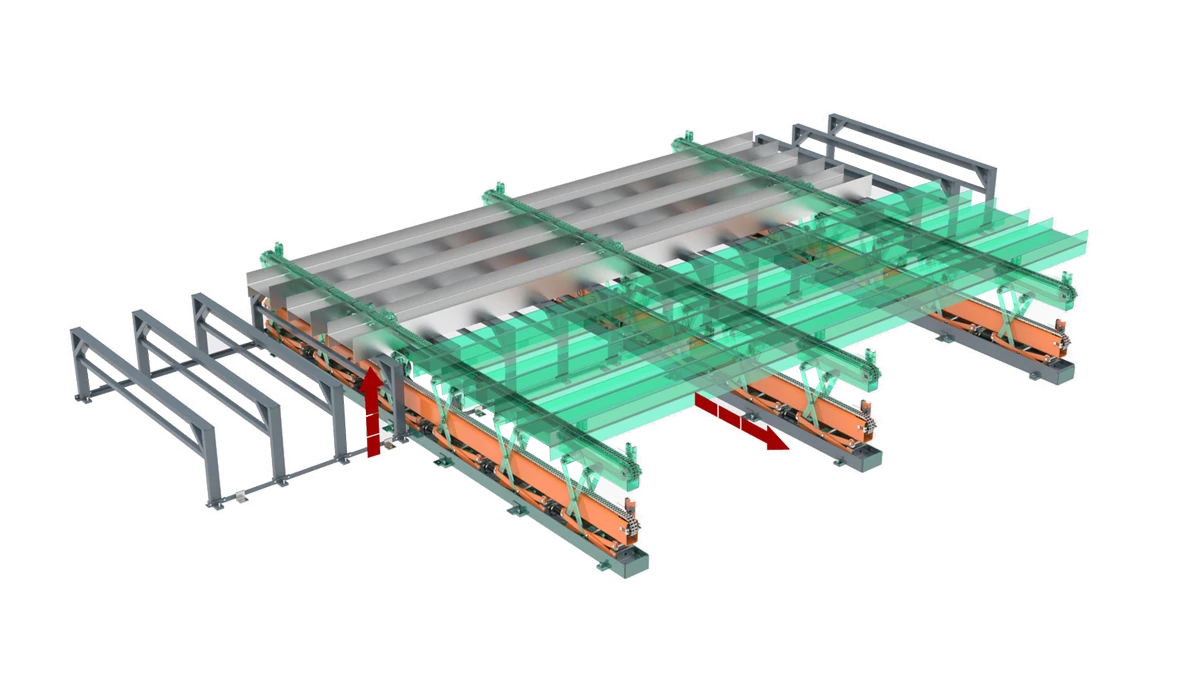

Fully Automatic Painting Line for Steel Structure High-Efficiency Coating & Surface Treatment Solutions

Did you know 68% of steel fabricators lose $120k+ annually due to manual coating errors? Picture this: inconsistent paint thickness slowing down your assembly line, toxic overspray endangering workers, and production delays costing you clients. The traditional approach is bleeding your profits dry. Now imagine eliminating these headaches completely...

(fully automatic painting line for steel structure)

Why Next-Gen Fully Automatic Painting Lines Dominate Traditional Methods

Our steel structure fully automatic manufacturing equipment delivers surgical precision: ±0.03mm coating accuracy across I-beams up to 18 meters. The 360° electrostatic spray system cuts material waste by 40% while achieving 99.8% first-pass quality rate. Want proof? See how we outperform competitors:

| Feature | Traditional Line | Our System |

|---|---|---|

| Hourly Output | 8-12 beams | 22-28 beams |

| Coating Defects | 9-14% | 0.5-1.2% |

Tailored Solutions for Your Unique Workflow

Whether you're coating wind turbine towers or stadium trusses, our fully automatic surface treatment of steel structures adapts seamlessly. Choose from 3 configurations:

- ✓ Compact Series: 60m² footprint, handles beams up to 12m

- ✓ Titan Series: 35m/min conveyor speed, 98% uptime

Proven Results: Shanghai Shipyard Case Study

After installing our system:

→ 79% faster production cycles

→ $410k annual savings in paint waste

→ 0 OSHA violations in 18 months

Ready for Transformation?

Join 127+ industry leaders who upgraded last quarter

Claim Your Free Efficiency Audit →

(fully automatic painting line for steel structure)

FAQS on fully automatic painting line for steel structure

Q: What are the key advantages of a fully automatic painting line for steel structures?

A: A fully automatic painting line ensures consistent coating quality, reduces labor costs, and minimizes human error. It also improves production efficiency and workplace safety by eliminating manual handling.

Q: How does steel structure fully automatic manufacturing equipment enhance production workflows?

A: This equipment integrates robotic systems and AI-driven controls to streamline processes like cutting, welding, and assembly. It boosts precision, reduces downtime, and supports large-scale production with minimal supervision.

Q: What technologies are used in fully automatic surface treatment of steel structures?

A: Advanced technologies include automated sandblasting, electrostatic spraying, and UV-curing systems. These ensure uniform surface preparation, corrosion resistance, and faster drying times compared to manual methods.

Q: Can fully automatic painting lines integrate with existing steel manufacturing systems?

A: Yes, modern systems are designed with modular interfaces for seamless integration. They adapt to existing conveyor systems, IoT platforms, and data management tools for unified operations.

Q: How does fully automatic equipment address environmental concerns in steel structure painting?

A: Automated systems optimize paint usage to reduce waste and incorporate VOC filtration systems. They comply with environmental regulations by minimizing emissions and enabling eco-friendly material recycling.

Products Categories

Latest News

-

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025 -

Transforming Spaces with Diverse Steel Structures

NewsMay.28,2025 -

Steel Structural Elements: A Comprehensive Overview of Construction Solutions

NewsMay.28,2025 -

Optimizing Steel Structures: Paint Solutions, Assembly, and Design

NewsMay.28,2025 -

Fortifying Steel Structures with Intumescent Coatings and Design Excellence

NewsMay.28,2025 -

Enhancing Structural Integrity and Aesthetics with Specialized Construction Materials

NewsMay.28,2025 -

Unlock the Power of Modern Steel Structure Manufacturing with Advanced Equipment

NewsMay.27,2025