- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Mar . 05, 2025 07:23

Back To List

containerhanteringsutrustning

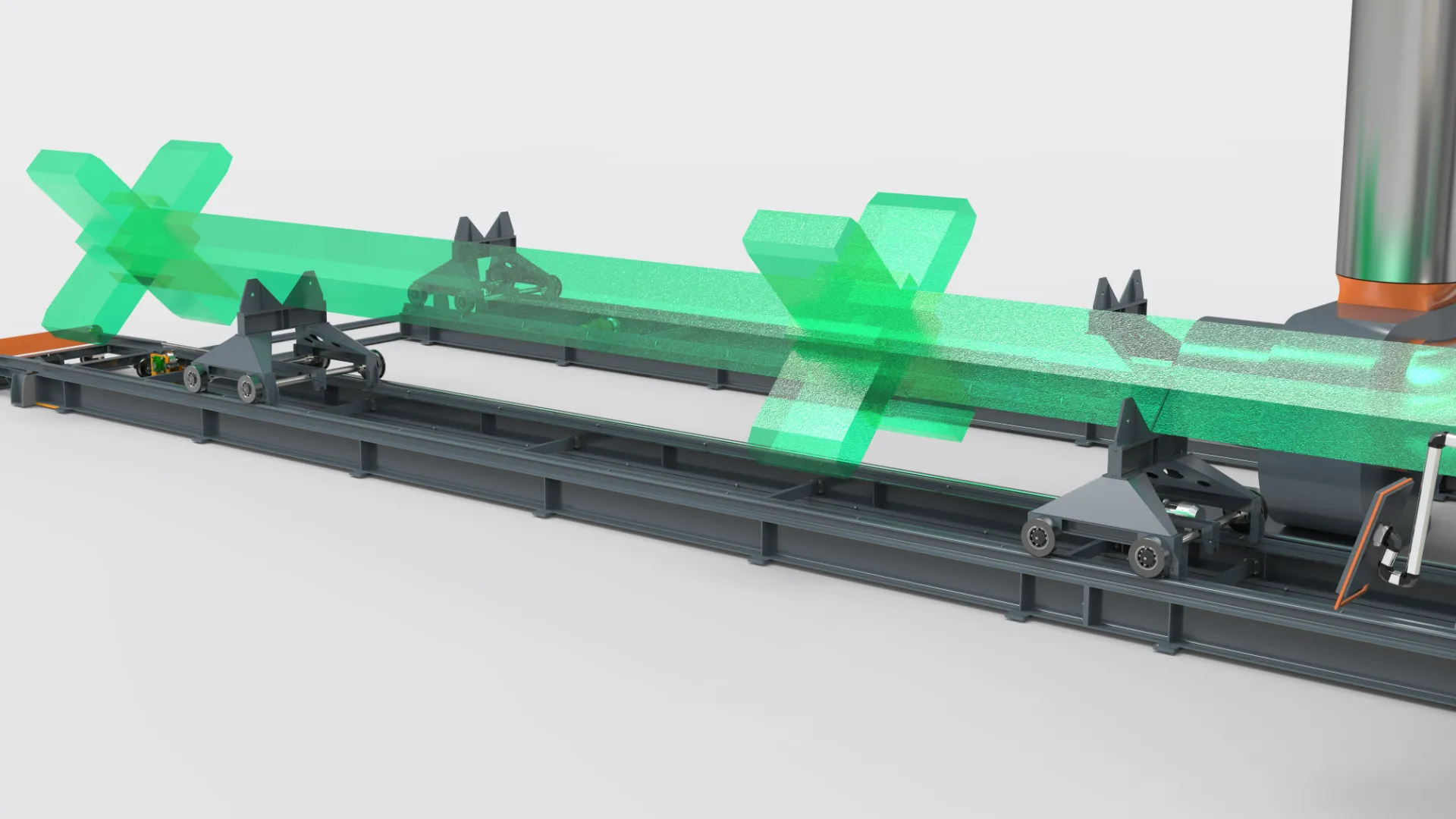

Container handling equipment plays a crucial role in the logistics and shipping industry, ensuring the safe and efficient movement of goods across the world. This sophisticated machinery is designed to lift, transport, and place containers, whether at bustling ports, expansive warehouses, or sprawling logistic hubs.

To ensure the reliability and longevity of container handling equipment, regular maintenance and skilled operation are essential. Operators and maintenance technicians must possess in-depth knowledge and expertise to diagnose and address potential mechanical issues swiftly, thereby minimizing downtime. Comprehensive training programs and certifications are critical in cultivating this expertise, ensuring that personnel are not only competent but also adhere to the highest standards of safety and operational excellence. Investing in high-quality container handling equipment requires a significant financial commitment; however, the benefits far outweigh the costs. The use of top-tier equipment not only maximizes operational efficiency but also enhances a company’s reputation for reliability and professionalism. This is especially true in an industry where timeliness and precision are paramount, and delays can have substantial financial repercussions. In the sphere of logistics and shipping, trustworthiness is paramount. Container handling equipment suppliers must therefore demonstrate a proven track record of product excellence and customer service. Building trust goes beyond offering durable products; it encompasses transparent communication, responsive support, and a commitment to continuous improvement. By fostering strong partnerships with clients, suppliers can ensure long-term success and mutual growth. In conclusion, container handling equipment is the backbone of efficient and effective logistics operations. The relentless pursuit of technological advancements and sustainable practices continues to redefine industry standards, proving that expertise, experience, authority, and trustworthiness are not merely desirable qualities but essential components driving the future of global trade.

To ensure the reliability and longevity of container handling equipment, regular maintenance and skilled operation are essential. Operators and maintenance technicians must possess in-depth knowledge and expertise to diagnose and address potential mechanical issues swiftly, thereby minimizing downtime. Comprehensive training programs and certifications are critical in cultivating this expertise, ensuring that personnel are not only competent but also adhere to the highest standards of safety and operational excellence. Investing in high-quality container handling equipment requires a significant financial commitment; however, the benefits far outweigh the costs. The use of top-tier equipment not only maximizes operational efficiency but also enhances a company’s reputation for reliability and professionalism. This is especially true in an industry where timeliness and precision are paramount, and delays can have substantial financial repercussions. In the sphere of logistics and shipping, trustworthiness is paramount. Container handling equipment suppliers must therefore demonstrate a proven track record of product excellence and customer service. Building trust goes beyond offering durable products; it encompasses transparent communication, responsive support, and a commitment to continuous improvement. By fostering strong partnerships with clients, suppliers can ensure long-term success and mutual growth. In conclusion, container handling equipment is the backbone of efficient and effective logistics operations. The relentless pursuit of technological advancements and sustainable practices continues to redefine industry standards, proving that expertise, experience, authority, and trustworthiness are not merely desirable qualities but essential components driving the future of global trade.

Next:

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025