- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

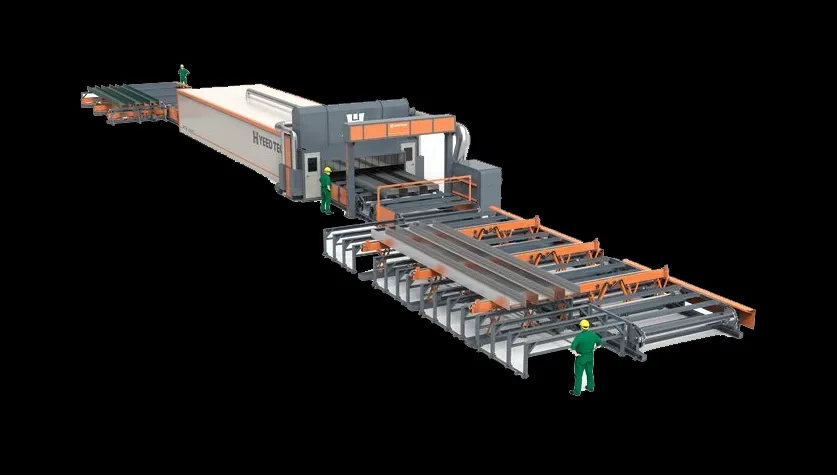

Unlock the Power of Modern Steel Structure Manufacturing with Advanced Equipment

As industries continue to evolve, the need for efficient and durable steel structures is more crucial than ever. From skyscrapers to industrial warehouses, the reliability and strength of steel structures are fundamental to modern construction. To achieve high performance and superior quality, teraskonstruktsioonide pinnatöötlusseadmed and intelligent manufacturing technologies are essential. These innovations not only improve the structural integrity of steel but also optimize production processes, reducing costs and enhancing precision in the final product.

Steel Structure Surface Treatment Equipment – Enhancing Durability and Performance

One of the key steps in the production of steel structures is teraskonstruktsioonide pinnatöötlusseadmed. This technology is designed to clean, prepare, and protect steel surfaces, ensuring they are free of rust, dirt, and other contaminants. By using advanced techniques such as sandblasting, shot blasting, and chemical treatments, teraskonstruktsioonide pinnatöötlusseadmed ensures that the surface is ideal for further processing and coating. This equipment plays a critical role in extending the lifespan of steel structures by enhancing their resistance to corrosion, wear, and harsh environmental conditions. Whether for industrial buildings or large-scale infrastructure projects, teraskonstruktsioonide pinnatöötlusseadmed guarantees that the final product meets the highest standards of durability and performance.

Revolutionizing Production with Steel Structure Intelligent Manufacturing Equipment

Sissejuhatus steel structure intelligent manufacturing equipment has significantly changed the landscape of industrial production. By integrating advanced sensors, artificial intelligence, and robotics, this equipment streamlines the entire manufacturing process. From material handling to automated welding and assembly, steel structure intelligent manufacturing equipment allows for precise control over every aspect of production. This level of automation reduces human error, enhances consistency, and increases production speed, all while maintaining the highest standards of quality. Companies can now produce steel structures with greater efficiency, lower labor costs, and reduced waste, making intelligent manufacturing equipment a game-changer in the steel fabrication industry.

Fully Automatic Steel Structure Manufacturing Equipment – Unmatched Efficiency

Tõus steel structure fully automatic manufacturing equipment marks a new era of manufacturing efficiency. This equipment can handle every stage of steel structure production—from cutting and shaping to welding and finishing—automatically. Fully automated systems are designed to work without continuous human supervision, allowing for 24/7 operation. With features like programmable logic controllers (PLCs) and real-time monitoring, steel structure fully automatic manufacturing equipment ensures that the production process is not only efficient but also highly customizable to meet specific project requirements. Whether it’s a large industrial plant or a complex architectural structure, fully automatic manufacturing systems ensure consistent quality and rapid production turnaround.

Benefits of Fully Automated Surface Treatment in Steel Manufacturing

With fully automatic surface treatment of steel structures, manufacturers can achieve consistent and repeatable results without manual intervention. This automation ensures that the steel surfaces are treated with the correct level of precision, improving adhesion for coatings and paint while also extending the life of the structure. Automated systems are designed to handle complex tasks such as chemical spraying, heat treatment, and coating application, ensuring that every surface is treated uniformly.

Why Choose Advanced Steel Structure Equipment for Modern Manufacturing?

When investing in teraskonstruktsioonide valmistamise seadmed, it's essential to consider the technological advancements that modern systems offer. Not only do they enhance productivity, but they also contribute to greater safety and environmental responsibility. By integrating automation and AI, the latest steel structure equipment offers features like real-time quality control, predictive maintenance, and energy-efficient operations. These benefits not only improve the overall quality of steel structures but also ensure that manufacturers can keep pace with increasing demand while maintaining competitive pricing.

FAQs – Steel Structure Manufacturing Equipment

Q: What are the advantages of using steel structure surface treatment equipment?

A: Steel structure surface treatment equipment improves the durability of steel by preparing surfaces for coating and protecting them from corrosion. This ensures a longer lifespan for steel structures, even in harsh environments.

Q: How does steel structure intelligent manufacturing equipment increase efficiency?

A: Steel structure intelligent manufacturing equipment uses AI and automation to streamline production, reduce labor costs, and ensure high-quality results with minimal errors.

Q: What makes fully automatic manufacturing systems superior?

A: Steel structure fully automatic manufacturing equipment allows for continuous, high-speed production without human intervention, increasing efficiency and ensuring consistent product quality.

Q: How does fully automatic surface treatment improve steel manufacturing?

A: Fully automatic surface treatment of steel structures ensures uniform application of coatings and treatments, improving both the quality of the finish and the longevity of the steel structures.

Q: Why is automation in steel structure production important for modern industries?

A: Automation in steel structure production reduces production times, increases precision, and lowers operational costs, making it essential for manufacturers to remain competitive in today’s market.

Toodete kategooriad

Viimased uudised

-

Unmatched Mobility and Efficiency in Container Handling Equipment

UudisedJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

UudisedJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

UudisedJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

UudisedJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

UudisedJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

UudisedJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

UudisedMay.28,2025