- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Steel Structure Automatic Painting Line: High-Efficiency Automated Spraying

Yeed Tech Co.,Ltd. - Industrial Automation Leaders

As a pioneer in industrial coating solutions, Yeed Tech specializes in developing advanced painting systems with precision engineering and robust automation capabilities. Our R&D team combines European design standards with Chinese manufacturing expertise to deliver exceptional performance.

Our Flagship Solution: Steel Structure Automatic Painting Line

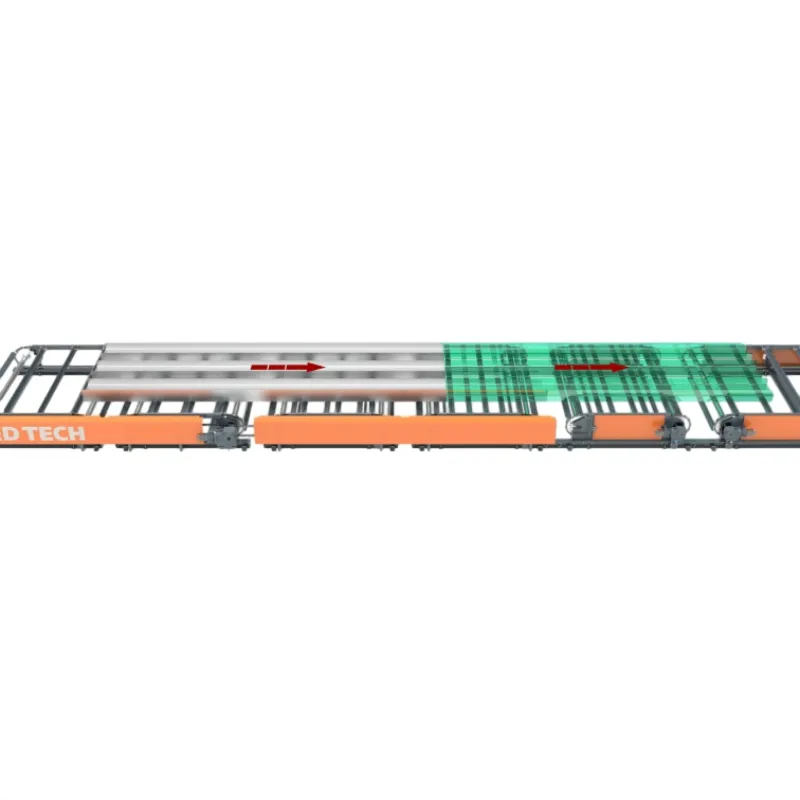

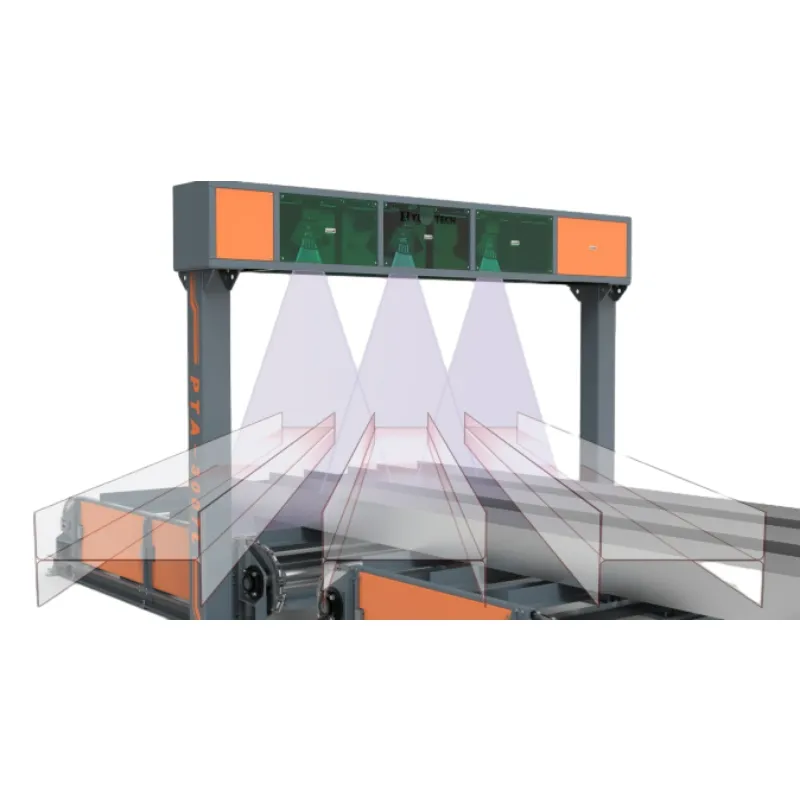

The Steel Structure Automatic Painting Line revolutionizes surface treatment with advanced safety and efficiency features. Engineered with a scissor lift design providing 3.5T single load-bearing capacity, it prevents component damage during transport. Integrated safety detection systems enable simultaneous painting of multiple components while automatic speed adjustment optimizes coating workflow.

Technical Specifications Comparison

| Parameter | Yeed Tech Standard | Industry Average | Premium Models |

|---|---|---|---|

| Throughput Capacity | 35-45 tons/hour | 25-35 tons/hour | 40-50 tons/hour |

| Paint Transfer Efficiency | 85-90% | 70-80% | 90-95% |

| Scissor Lift Capacity | 3.5T | 2.0-2.8T | 4.0T |

| Drying Time | 15-20 minutes | 25-35 minutes | 12-18 minutes |

| Energy Consumption | 45-55 kW/h | 60-70 kW/h | 40-48 kW/h |

| Conveyor Speed Range | 0.5-4.0 m/min | 0.4-3.0 m/min | 0.6-5.0 m/min |

Advanced Steel Structure Automatic Painting Line in Action

Industry Evolution and Steel Structure Automatic Painting Line Technology

The global market for industrial coating equipment is projected to reach $23.7 billion by 2027 (MarketsandMarkets Report). This growth is primarily driven by infrastructure development and stricter environmental regulations requiring advanced coating solutions.

Steel Structure Automatic Painting Line systems have evolved significantly in recent years with three critical advancements:

- Precision Application Systems: Advanced electrostatic spray technology achieves 10-15% better coverage with 20% less material waste compared to traditional methods.

- Intelligent Process Control using IoT sensors to monitor temperature, humidity and viscosity in real-time with 99.3% process accuracy as reported by the Journal of Industrial Coatings.

- Environmental Compliance systems that capture and recycle over 95% of VOC emissions, meeting Euro 6D standards without compromising throughput rates.

Steel Structure Automatic Painting Line Application Scenarios

Construction & Infrastructure

Corrosion protection for bridges, stadiums, and high-rise buildings where the Steel Structure Automatic Painting Line ensures uniform coating on complex structural members.

Manufacturing Facilities

Automotive plants and heavy machinery factories requiring durable surface treatment for production equipment and structural components.

Energy Sector

Wind turbine towers and power transmission structures requiring specialized coatings resistant to extreme weather conditions.

Marine & Offshore

Specialized painting systems for ship components and offshore platforms demanding corrosion resistance in saltwater environments.

Technical FAQ: Steel Structure Automatic Painting Line

What safety mechanisms prevent component damage?

The Steel Structure Automatic Painting Line integrates laser alignment sensors and collision avoidance systems with 5mm precision tolerance to protect components throughout the painting process.

What coating thickness accuracy can be achieved?

Our systems maintain ±5 micron coating thickness consistency across structural elements using ultrasonic measurement technology documented in Industrial Coating Review (Vol. 42).

What environmental standards do these systems meet?

Compliant with ISO 14001, EPA Tier 4 Final, and EU Industrial Emissions Directive standards with 95% VOC capture efficiency as certified by SGS International.

How is drying time optimized?

Through infrared zone control and airflow management achieving 25% faster curing than conventional systems without compromising film integrity.

What maintenance requirements are there?

Automated nozzle cleaning cycles every 8 hours of operation with predictive maintenance alerts through our Y-Link monitoring system.

Can the system handle diverse component sizes?

Adjustable conveyor systems accommodate components from 1m to 25m in length with specialized fixtures ensuring consistent coating application.

What automation integrations are available?

Compatible with MES systems through OPC UA protocol and offers SAP connectivity for production tracking as outlined in Automation World's Factory Integration Guide.

Industry Research & Technical References

The global authority on corrosion control standards referenced by engineers worldwide.

Definitive guide to structural steel treatment and protection methodologies.

Cutting-edge research on industrial coating technologies and environmental impacts.

Upgrade to Precision Coating Technology

Discover how our Steel Structure Automatic Painting Line can enhance your manufacturing capabilities while reducing operational costs.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025