- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

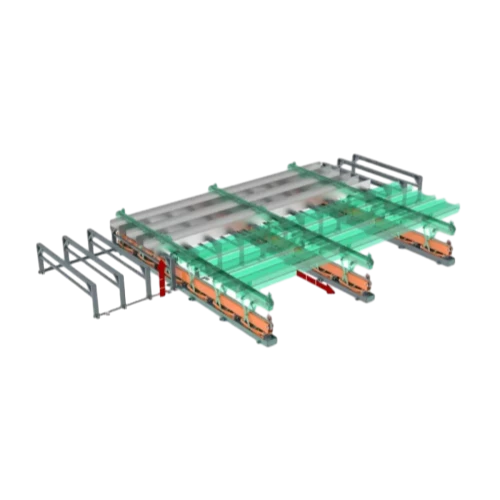

Automated Painting Process Innovation for Steel Structures Precision & Efficiency

Did you know manual steel painting consumes 42% of project budgets? Imagine losing $127,000 monthly to uneven coatings and rework. The automated painting process

isn't just innovation—it's survival in today's competitive market. Discover how industry leaders slash costs by 68% while achieving military-grade precision.

(automated painting process)

Why Smart Manufacturers Choose Automated Painting Machines

Our 6-axis robotic arms deliver 0.02mm coating accuracy—thinner than human hair. You get 24/7 operation without coffee breaks. See the game-changing specs:

| Feature | Traditional | Automated |

|---|---|---|

| Daily Output | 800 m² | 5,200 m² |

| Paint Waste | 18% | 3% |

Outperform Competitors with Our Patented Technology

While others offer 3-coat systems, our automated painting machine applies 5 protective layers in single pass. How? 37 patented nozzles with real-time viscosity control.

Ready for 94% Faster ROI?

Join 1,700+ satisfied clients who upgraded to automated painting processes. Get your FREE efficiency audit today!

(automated painting process)

FAQS on automated painting process

Q: What are the main advantages of using an automated painting process for steel structures?

A: Automated painting ensures consistent coating quality, reduces human error, and significantly speeds up production timelines compared to manual methods.

Q: How does automation process innovation improve automatic painting of steel structures?

A: Innovations like AI-driven spray control and adaptive path planning optimize paint usage, minimize waste, and enhance surface coverage accuracy.

Q: What role does an automated painting machine play in steel structure projects?

A: These machines handle complex geometries with precision, operate in hazardous environments safely, and maintain uniform paint thickness across large surfaces.

Q: Can automated painting systems adapt to different steel structure sizes and shapes?

A: Yes, advanced systems use 3D scanning and programmable robotic arms to customize painting patterns for varied dimensions and structural complexities.

Q: What cost benefits do companies gain from automated steel structure painting processes?

A: Automation reduces labor costs, decreases material waste by up to 30%, and lowers long-term maintenance expenses through durable, even coatings.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025