- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

студ . 17, 2025 05:52

Back To List

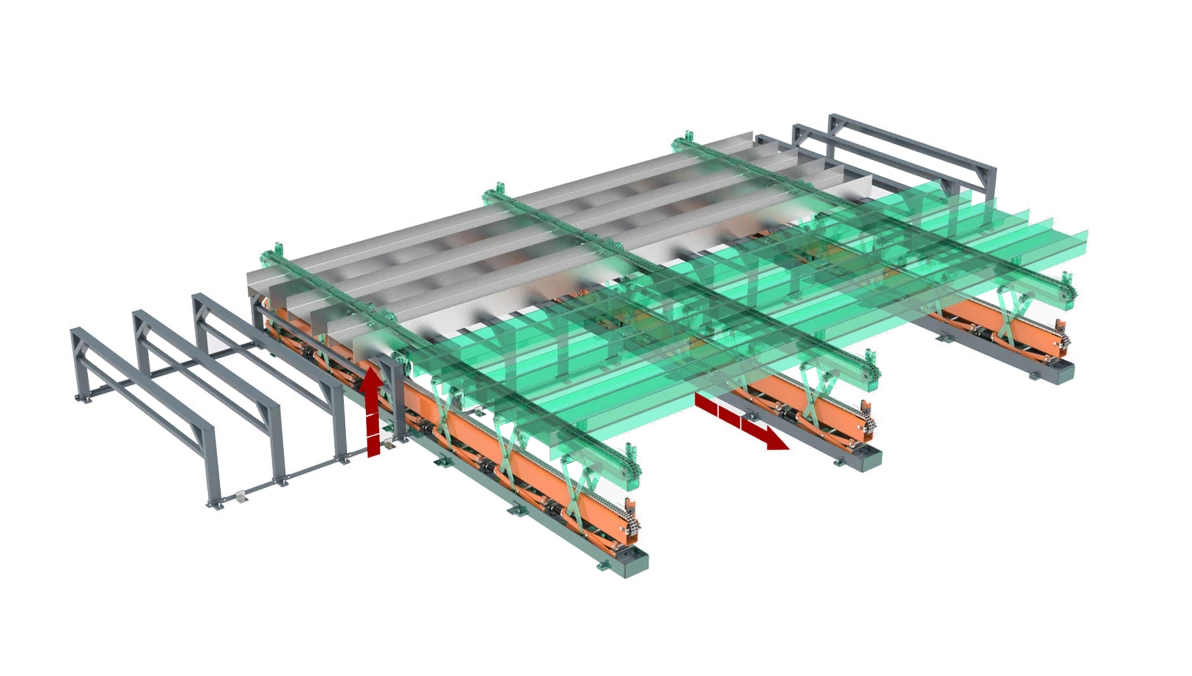

Steel Structure Automatic Painting Line

Automatic spray painting has redefined the concept of efficiency and precision in the field of surface coating. For industries and hobbyists alike, the automation of spray painting is nothing short of a revolution, bringing forth unparalleled consistency and a refined touch to projects. With ever-evolving technological advancements, the domain of automatic spray painting has broadened, offering solutions that are increasingly adaptable and precise for a range of applications.

Expertise in System Integration Implementing an automatic spray painting solution requires a sophisticated understanding of both the technology and the specific application context. Success comes from integrating these systems into existing production lines without disrupting workflow. Companies that specialize in automatic spray solutions bring this expertise, often offering customized system design, installation, and ongoing maintenance to ensure peak performance. Building Trust Through Proven Results The reliability and success of automatic spray painting systems can be seen in their widespread adoption across industries. Manufacturers and production facilities invest heavily in these systems, not only because of the immediate efficiency gains but also due to the long-term benefits in quality control and resource management. The track record of these systems builds trust, signaling to clients and customers that a company is committed to delivering consistent quality while also being environmentally conscious. The Future of Automatic Spray Painting The future of automatic spray painting is exciting, with ongoing advancements in robotics and artificial intelligence promising even greater levels of adaptability and precision. The coming years are likely to see these systems become even more closely integrated with digital production environments, utilizing big data and IoT (Internet of Things) technologies to perform predictive maintenance and optimize paint consumption dynamically. In conclusion, automatic spray painting represents the pinnacle of modern coating solutions, aligning the need for high efficiency with precision and environmental responsibility. As technology continues to evolve, businesses relying on these advanced systems will not only maintain but enhance their competitive edge in their respective fields.

Expertise in System Integration Implementing an automatic spray painting solution requires a sophisticated understanding of both the technology and the specific application context. Success comes from integrating these systems into existing production lines without disrupting workflow. Companies that specialize in automatic spray solutions bring this expertise, often offering customized system design, installation, and ongoing maintenance to ensure peak performance. Building Trust Through Proven Results The reliability and success of automatic spray painting systems can be seen in their widespread adoption across industries. Manufacturers and production facilities invest heavily in these systems, not only because of the immediate efficiency gains but also due to the long-term benefits in quality control and resource management. The track record of these systems builds trust, signaling to clients and customers that a company is committed to delivering consistent quality while also being environmentally conscious. The Future of Automatic Spray Painting The future of automatic spray painting is exciting, with ongoing advancements in robotics and artificial intelligence promising even greater levels of adaptability and precision. The coming years are likely to see these systems become even more closely integrated with digital production environments, utilizing big data and IoT (Internet of Things) technologies to perform predictive maintenance and optimize paint consumption dynamically. In conclusion, automatic spray painting represents the pinnacle of modern coating solutions, aligning the need for high efficiency with precision and environmental responsibility. As technology continues to evolve, businesses relying on these advanced systems will not only maintain but enhance their competitive edge in their respective fields.

Next:

Products Categories

Latest News

-

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025 -

Transforming Spaces with Diverse Steel Structures

NewsMay.28,2025 -

Steel Structural Elements: A Comprehensive Overview of Construction Solutions

NewsMay.28,2025 -

Optimizing Steel Structures: Paint Solutions, Assembly, and Design

NewsMay.28,2025 -

Fortifying Steel Structures with Intumescent Coatings and Design Excellence

NewsMay.28,2025 -

Enhancing Structural Integrity and Aesthetics with Specialized Construction Materials

NewsMay.28,2025 -

Unlock the Power of Modern Steel Structure Manufacturing with Advanced Equipment

NewsMay.27,2025