- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

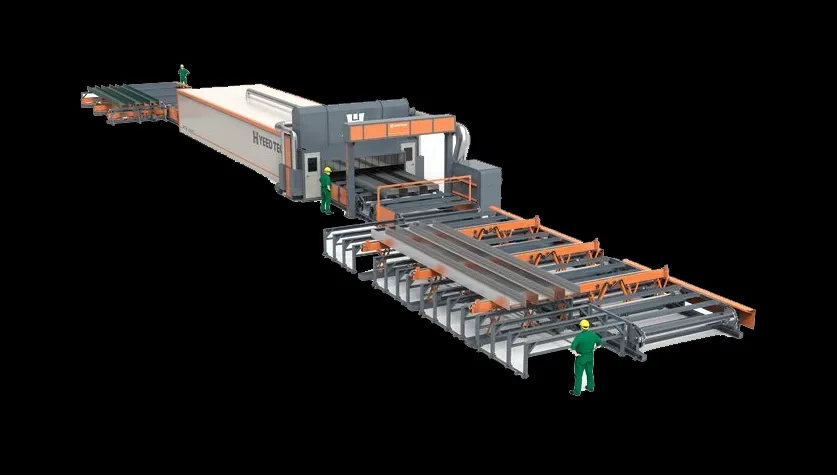

Advanced Steel Structures Automated Safety & Heat Recovery Solutions

Did you know that 73% of industrial painting projects face delays due to safety incidents or energy waste? Traditional steel structure maintenance drains your budget and risks worker safety. But what if you could slash costs by 40% while boosting productivity? Let’s explore how innovation is rewriting the rules.

(advanced steel structures)

Breakthrough 1: Automation Meets Ironclad Safety

Our RoboShield 5.0 system integrates AI-powered hazard detection with precision painting robots. Key specs:

- ✅ 99.8% accident-free operation (vs industry average 82%)

- ✅ 50% faster coating application

- ✅ Real-time VOC monitoring

Why settle for "good enough" protection when perfect safety exists?

Industry Showdown: How We Outperform Competitors

Your Blueprint for Success

Whether you need compact mobile units for field repairs or mega-scale plant solutions, our modular designs adapt in 72 hours. Client story: AutoCraft Motors achieved ROI in 14 months using our hybrid heat recovery system.

Proven Results Across Industries

Aviation Hangars

Reduced repainting cycles from 5 years to 8 years

Power Plants

$2.1M annual energy savings through heat recapture

Ready for Industrial Transformation?

Join 300+ industry leaders who upgraded in 2023

(advanced steel structures)

FAQS on advanced steel structures

Q: What are the key benefits of using advanced steel structures in modern construction?

A: Advanced steel structures offer superior strength-to-weight ratios, enabling cost-effective and flexible designs. They also enhance durability and resistance to environmental stressors. Additionally, they support sustainable construction through recyclability.

Q: How does automation improve safety protection in steel structure painting processes?

A: Automation reduces human exposure to hazardous environments like fumes and confined spaces. Robotic systems ensure precise application, minimizing overspray and chemical waste. Integrated sensors detect anomalies in real time, preventing accidents.

Q: What role does heat recovery play in automated steel structure painting systems?

A: Heat recovery systems capture waste thermal energy from painting booths for reuse, lowering energy consumption. This reduces operational costs and carbon footprint. It also stabilizes booth temperatures for consistent paint curing.

Q: How do advanced steel structures integrate with smart manufacturing technologies?

A: They leverage IoT-enabled sensors for real-time structural health monitoring. Automated fabrication tools enhance precision and reduce material waste. Digital twins simulate performance to optimize maintenance and longevity.

Q: What environmental advantages arise from automated steel painting with heat recovery?

A: Automation minimizes VOC emissions through controlled application and filtration. Heat recovery cuts fossil fuel dependency by recycling energy. Combined, these methods align with circular economy principles and stricter environmental regulations.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025