- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

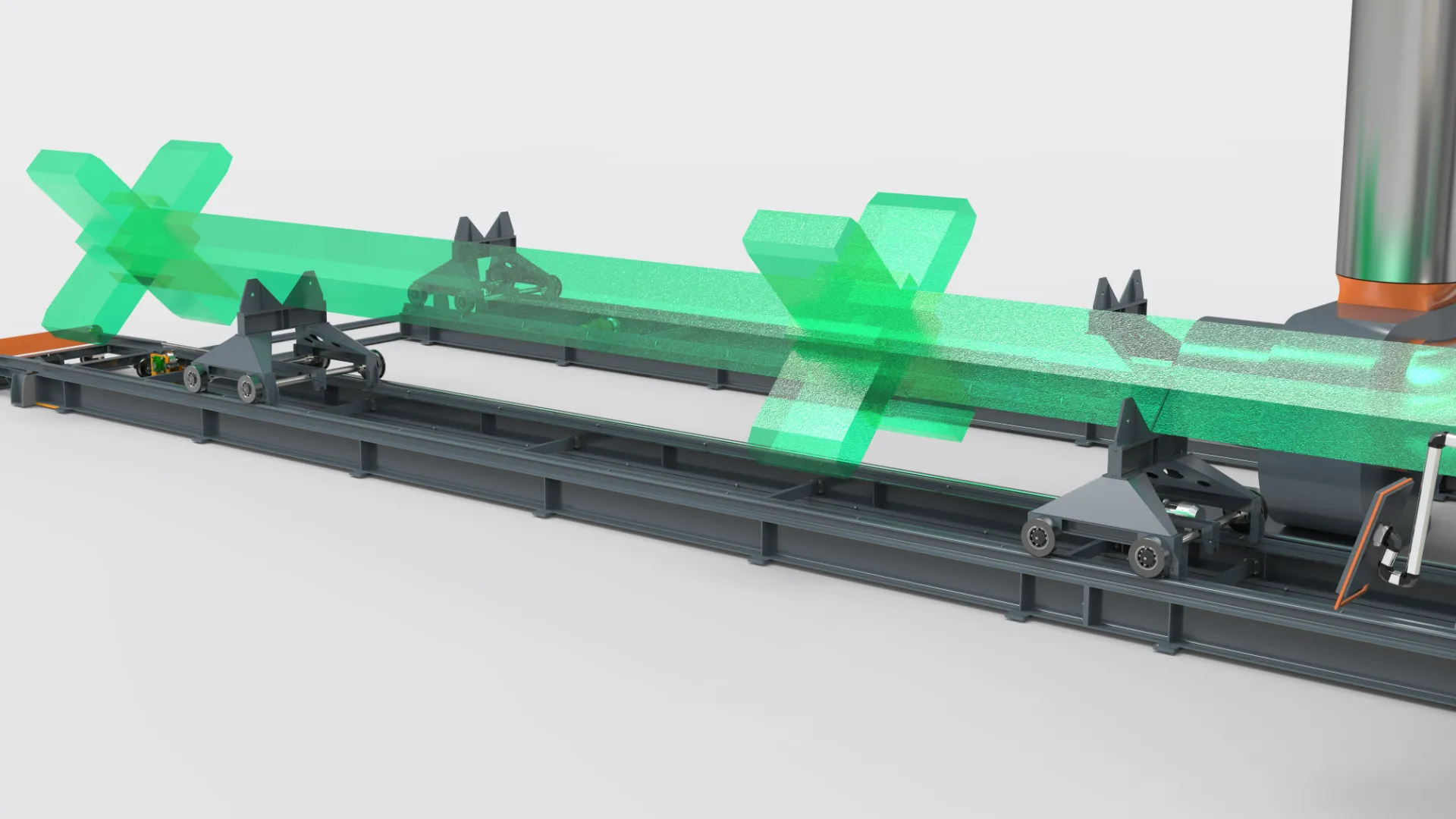

Automatic Management of Energy Consumption of Automatic Painting of Steel Structure Smart Energy-Saving Line Design

Steel construction isn’t just about strength. Efficiency defines industry leaders. Did you know that traditional steel structure painting lines consume 35% more energy than automated lines with proper management? Rising energy costs and stricter sustainability demands hit your bottom line hard. Imagine slashing costs, reducing carbon output, and boosting speed—all at once. That's the power of automatic management of energy consumption of automatic painting of steel structure

. Ready to discover how?

(automatic management of energy consumption of automatic painting of steel structure)

Smart Tech, Smarter Savings: The Core Benefits

Automatic management of energy consumption of automatic painting of steel structure combines IoT sensors, AI algorithms, and tailored software. The result? Real-time energy monitoring and adaptive control. Systems automatically adjust spray gun speed, conveyor flow, and exhaust fans. This means machines work exactly when and how they should—no more, no less.

What does this mean for you? Energy savings up to 28% on every project. That could mean thousands in annual savings. Downtime drops by half. Paint waste? Virtually eliminated with automatic management of paint for automatic painting of steel structure. You gain greater consistency, better environmental compliance, and quality that keeps clients happy.

- Energy reduction: Up to 28% lower power bills

- Carbon footprint: Down by 22% on average

- Operation time saved: Up to 12h/week

- Paint usage: 17% less annual waste

How Do Leading Vendors Compare?

The industry is crowded. But not all solutions are equal. The table below shows how top players stack up:

Why settle for less? Choose proven results with the right partner in steel structure painting line energy-saving energy design.

Custom Solutions for Every Line

Every production line is unique. That’s why leading providers insist on tailored approaches. Advanced systems analyze your paint usage, energy profile, and workflow. Custom algorithms are deployed—sometimes within days. You get easy-to-use dashboards and mobile control, too.

- IoT sensors track real-time temperatures, humidity, and usage

- AI calibrates every stage: pre-paint, painting, drying

- Alerts and automation mean zero manual oversight

- Energy optimization aligned to your plant’s actual needs

Integrate effortlessly. No disruptions. Training is included, so even new operators are up to speed in hours.

Real-World Results: Success Stories

Take the example of TitanFab, a mid-size steel fabricator in Illinois. Before automation, their energy bills were soaring. After embracing automatic management of paint for automatic painting of steel structure, they saw:

- Annual energy spend dropped by $48,000

- CO₂ output decreased 19%

- Zero shutdowns for recalibration in 18 months

- Paint line throughput up by 23%

It’s not just big names. Small and agile shops love the flexibility and gains found with smart energy management and customized paint controls.

Ready for the Next Step?

Why let outdated systems hold your team back? Transform your steel structure projects with advanced automatic management of energy consumption of automatic painting of steel structure—and start saving from day one. As a leader in steel structure painting line energy-saving energy design, we offer full-service integration, support, and ongoing optimization. Don’t delay—contact us now for a free tailored demo and see measurable results in your first month! The future of steel structure manufacturing is smarter and greener—be part of it today.

(automatic management of energy consumption of automatic painting of steel structure)

FAQS on automatic management of energy consumption of automatic painting of steel structure

Q: What is the automatic management of energy consumption of automatic painting of steel structure?

A: It refers to using intelligent systems to monitor and optimize the energy use in automated steel structure painting lines. This reduces unnecessary energy wastage. The process ensures painting quality while saving costs.Q: How does steel structure painting line energy-saving energy design work?

A: Energy-saving energy design involves the integration of efficient equipment and smart control systems. These systems minimize energy use during painting operations. The result is a more sustainable and cost-effective production line.Q: Why is automatic management of paint important in automatic painting of steel structures?

A: Automatic management of paint ensures precise dispensing and reduces paint wastage. It helps maintain consistent coating thickness and finish. This leads to improved product quality and cost savings.Q: What benefits does automatic energy management provide to steel structure painting lines?

A: Automatic energy management lowers electricity bills and reduces carbon emissions. It also enhances reliability and prolongs equipment lifespan. Together, these benefits increase overall production efficiency.Q: What technologies are commonly used in the automatic management of energy consumption in steel structure painting?

A: Technologies include IoT sensors, real-time monitoring software, and automated control systems. These work together to track, analyze, and optimize energy usage. Implementing these can lead to significant energy savings.Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025