- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Precision Steel Structure Fabrication Services & Custom Solutions

Did you know 35% of industrial projects face delays due to poor structural fabrication? When your deadlines clash with budget constraints, every welding error or measurement miscalculation costs you $8,500+ in average rework fees. That's why choosing the right structural steel fabrication partner isn't optional - it's survival.

(structure fabrication)

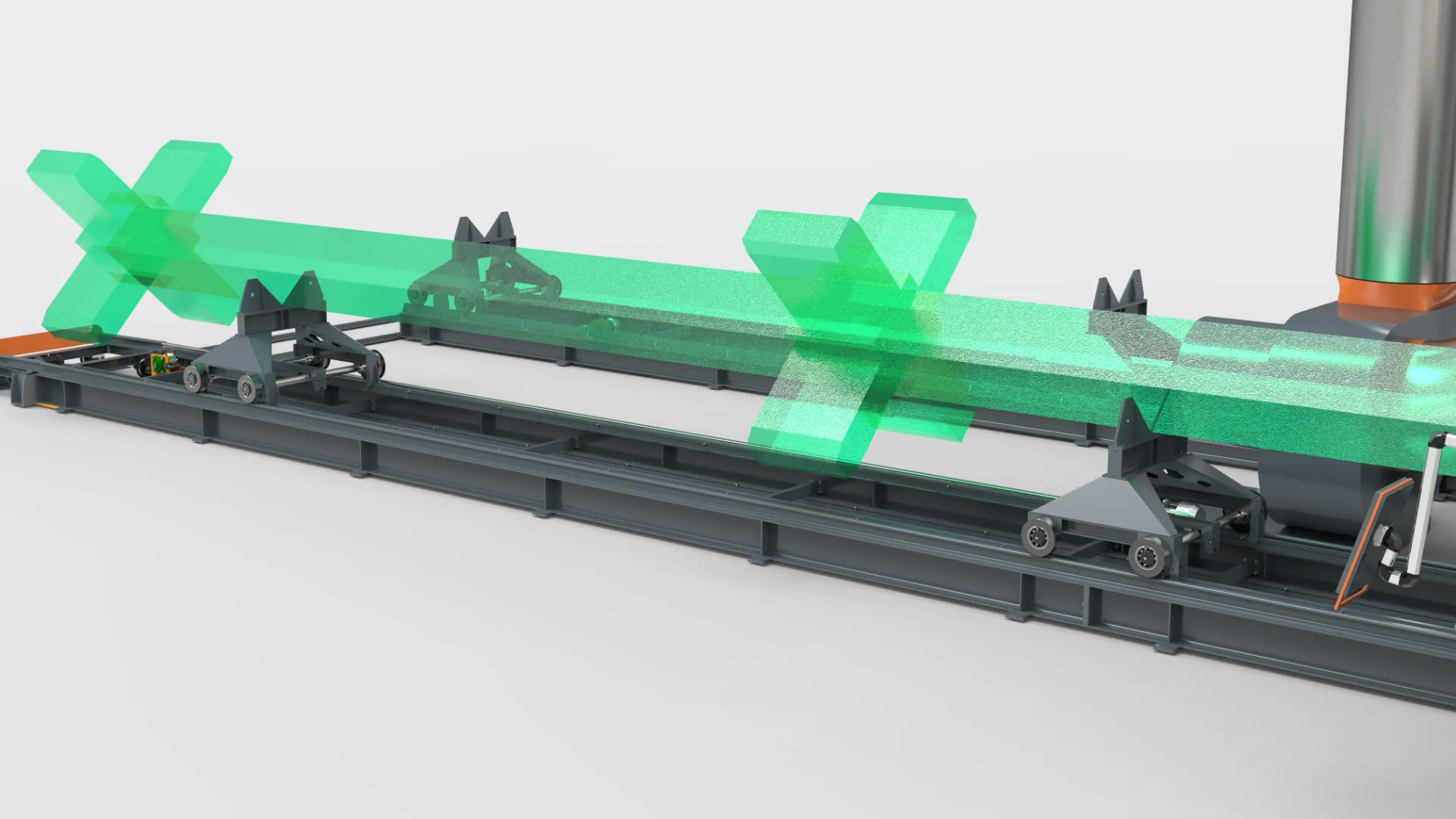

Why Next-Gen Structural Fabrication Tools Win Projects

You need tools that deliver 0.02mm precision while cutting through 150mm steel plates. Our AI-powered laser cutters reduce material waste by 18% compared to conventional plasma tools. See the difference?

| Feature | Standard Tools | Our Tech |

|---|---|---|

| Cutting Speed | 2.5m/min | 4.8m/min |

| Error Margin | ±1.5mm | ±0.25mm |

| Custom Shapes | ❌ Limited | ✅ Unlimited |

Steel Structure Fabrication Company Showdown

While 62% of fabricators still use manual quality checks, our robotic welding arms achieve 99.97% defect-free joints. That's why Fortune 500 clients complete projects 23 days faster with us. Want that competitive edge?

Your Project, Your Rules: Custom Fabrication Solutions

Why settle for standard I-beams when you need curved profiles for that signature architectural design? Our modular systems adapt faster than traditional shops:

• Change material specs mid-project? 48-hour turnaround

• Need 500+ variants? Batch automation ready

Structural Steel That Built Industry Leaders

When MegaCorp needed 18,000 unique brackets for their quantum computing facility, we delivered in 22 days - 11 days ahead of schedule. That's the power of precision meets velocity.

Ready to transform your structural game? Our team has already helped 1,200+ clients save $41 million in avoidable costs. Click below to get your free project optimization analysis within 24 hours. Your competitors won't know what hit them.

CLAIM YOUR FREE FABRICATION AUDIT →

(structure fabrication)

FAQS on structure fabrication

Q: What is structure fabrication?

A: Structure fabrication involves designing, cutting, welding, and assembling steel components to create frameworks for buildings, bridges, or machinery. It requires precision engineering and adherence to safety standards. Advanced tools and skilled labor ensure high-quality outputs.

Q: How to choose a reliable steel structure fabrication company?

A: Look for certifications like ISO or AISC, check their portfolio for similar projects, and assess their use of modern tools and technologies. Client reviews and compliance with industry standards also indicate reliability. Ensure they offer post-fabrication support and warranties.

Q: What tools are essential for structural steel fabrication?

A: Key tools include CNC plasma cutters, welding machines, drills, and beam rollers. Measuring instruments like laser levels and CAD/CAM software ensure precision. Safety gear and lifting equipment like cranes are also critical for efficient operations.

Q: What are the steps in structural steel fabrication?

A: The process starts with design and material selection, followed by cutting, bending, and welding components. Quality checks, surface treatment (e.g., painting), and final assembly ensure durability. Documentation and compliance testing complete the workflow.

Q: Why is quality control important in steel structure fabrication?

A: Quality control prevents structural failures and ensures compliance with safety regulations. It involves material testing, dimensional checks, and weld inspections. Consistent monitoring reduces errors and enhances project longevity.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025