- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Foster Your Coating Process with Intelligent Spray Technology

In today’s fast-paced manufacturing world, precision and efficiency are everything. Coating and finishing operations have evolved far beyond manual labor, thanks to the rise of smart, mechanized painting solutions. Investing in an automated spray painting machine not only ensures consistent quality across all products but also significantly reduces waste, labor costs, and application time. Whether you’re operating a small batch production line or a full-scale industrial facility, smart spray technology can completely transform your workflow with high-speed precision and reliability.

Automated Spray Painting Machine – Precision Meets Productivity

Awọn automated spray painting machine brings robotics and intelligent control systems into the paint booth, ensuring that every surface receives an even coat regardless of shape or complexity. These machines are ideal for repetitive, high-volume tasks where consistency is critical. With programmable patterns and adjustable nozzles, this technology minimizes overspray, improves finish quality, and significantly reduces downtime. By integrating one into your facility, you enhance not only output but also product quality, all while reducing operator fatigue.

Advanced Automated Paint Spray Systems for Every Industry

From automotive to furniture manufacturing, aládàáṣiṣẹ kun sokiri awọn ọna šiše are engineered to meet the demands of diverse industries. These systems use robotic arms, sensor-guided motion, and controlled pressure delivery to maintain a uniform application. The result is a smooth, flawless finish that reduces the need for rework or touch-ups. Because aládàáṣiṣẹ kun sokiri awọn ọna šiše operate with such accuracy, businesses can also enjoy material savings and lower environmental impact, aligning production with sustainability goals.

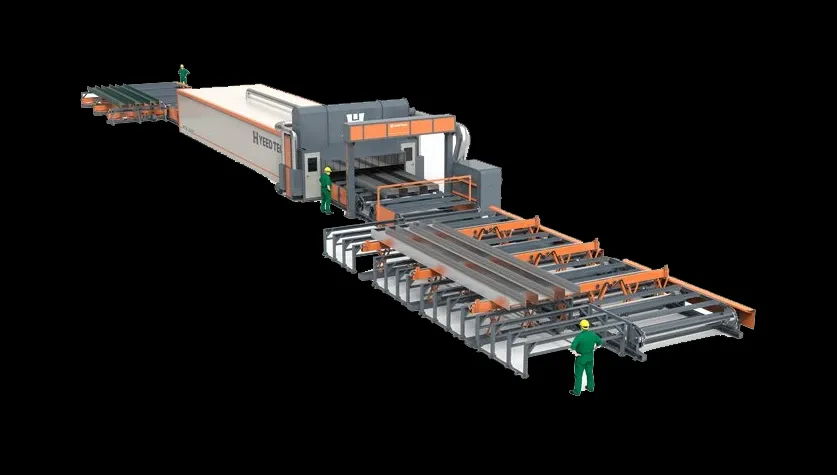

Automatic Spray Painting System with Conveyor – Continuous Coating Efficiency

A standout in production line automation is the laifọwọyi sokiri kikun eto pẹlu conveyor. This setup allows for non-stop operation, as products are automatically loaded, coated, and moved through drying tunnels without interruption. Ideal for wood panels, metal parts, or plastic casings, the laifọwọyi sokiri kikun eto pẹlu conveyor maximizes output while maintaining strict control over paint thickness and drying time. It’s a fully integrated solution designed to streamline even the most complex coating processes.

Why Conveyor-Based Systems Lead in Industrial Finishing

Using a laifọwọyi sokiri kikun eto pẹlu conveyor reduces human error and enhances production throughput. With options for enclosed booths, multi-angle spray heads, and temperature-controlled zones, manufacturers can achieve premium finishes without slowing down the line.

Versatile Automatic Spray Painting System for Any Scale

The modular design of the laifọwọyi sokiri kikun eto makes it suitable for operations of all sizes. Whether you’re looking to automate a single booth or connect an entire line, this technology can be tailored to your specific workflow. Advanced control panels let operators easily adjust speed, pattern, and paint volume, ensuring flawless results across different materials and product geometries. By adopting a fully automatic system, businesses improve consistency while lowering overall production costs.

Compact and Efficient Automatic Paint Sprayer for Workshops

When floor space is limited or projects vary in size, the automatic paint sprayer offers a compact, mobile alternative without sacrificing performance. Perfect for small workshops or specialized tasks, this sprayer delivers even coats with minimal overspray and paint loss. It can handle everything from primers to clear coats and is compatible with a variety of paint types. The automatic paint sprayer simplifies the finishing process and gives small teams the power of industrial-grade equipment in a portable package.

Application Versatility in One Compact Sprayer

Awọn automatic paint sprayer adapts quickly to different paint jobs, whether you’re coating a cabinet door or a custom metal part. Adjustable pressure settings and quick-change nozzles make it a favorite among finishers who need speed without compromising quality.

Automated Spray Painting System FAQs

Q: What’s the primary benefit of using an automated spray painting machine?

A: An automated spray painting machine ensures consistent application, reduces labor requirements, and eliminates the variability of manual painting.

Q: Are automated paint spray systems suitable for all materials?

A: Yes, aládàáṣiṣẹ kun sokiri awọn ọna šiše are designed to handle wood, plastic, metal, and more, offering flexibility and high-quality finishes across different substrates.

Q: How does a spray system with a conveyor improve production?

A: An laifọwọyi sokiri kikun eto pẹlu conveyor automates the loading, spraying, and drying processes, allowing for continuous, high-speed production with consistent quality.

Q: Can I customize an automatic spray painting system for my workshop?

A: Absolutely. The laifọwọyi sokiri kikun eto is modular and can be tailored to meet your space, speed, and application needs.

Q: What makes an automatic paint sprayer ideal for small-scale use?

A: The automatic paint sprayer offers industrial performance in a portable form, making it perfect for shops with limited space or for detailed, short-run projects.

Awọn ẹka Awọn ọja

Awọn irohin tuntun

-

Unmatched Mobility and Efficiency in Container Handling Equipment

IroyinJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

IroyinJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

IroyinJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

IroyinJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

IroyinJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

IroyinJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

IroyinMay.28,2025