- Top: 856Step on: 7

utility extension spring

People involved | Date:2025-08-14 06:52:54

Related articles

Conclusion

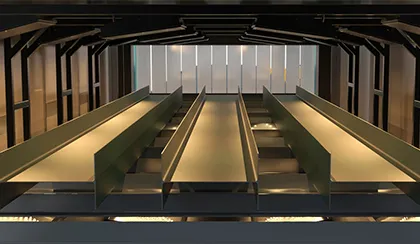

The adoption of robotic welders is quickly becoming a trend across various industries, particularly in advanced fabrication. These machines are designed to handle complex welding tasks with high accuracy, making them ideal for industries like automotive, aerospace, and heavy machinery. As companies look to streamline operations, welding arms equipped with automation capabilities offer a perfect solution for tackling projects that require tight tolerances and consistency.

- - Cost Reduction While the initial investment may be substantial, the reduction in labor costs and material waste will lead to lower overall operational expenses.

The Welding Fume Extraction System A Key Component in Workplace Safety

Заключение

Maintenance and Care

For those considering the transition to automated systems, understanding the initial investment versus long-term gains is essential. While the upfront cost may appear daunting, the return on investment is realized through improved throughput, lower labor costs, and reduced material waste. Consulting with experienced professionals during the planning and implementation phase is crucial, as they can provide insights tailored to specific industry needs and operational scales.

Comment area