- Top: 996Step on: 67364

Shijiazhuang TangChao Metal thick plant stakes

People involved | Date:2025-08-14 17:32:53

Related articles

Sustainability and the Future of Automatic Spraying Lines

The authority of automatic spray coating machines in the landscape of manufacturing technology is well-established. Market leaders in this domain, such as Nordson and Dürr, have consistently demonstrated their commitment to advancing the technology through innovative features that enhance machine performance. For instance, recent models incorporate vision systems that allow for real-time quality assessment and adaptive adjustments. This not only reduces human error but also elevates production standards, affirming the strategic value these machines bring to production processes.

automatic spray coating machineWhy Choose Yeed Tech Co., Ltd. for Your Fume Extraction Needs?

Sustainability Benefits of Automatic Spray Painting Systems

- 2. Weight Capacity The markings often include information about the maximum load capacity of the container. This helps operators understand how much weight can be safely lifted and transported, reducing the risk of accidents during handling.

3. Cast Iron Rods Cast iron rods are specifically formulated for welding cast iron components. They are essential in repairs where cast iron pots, pipes, or machinery need to be joined or mended.

One of the most important aspects of achieving seamless joints is maintaining a clean environment where the welding process can take place without interference. Welding smoke extractors are designed to capture and filter the fumes and smoke generated during welding, ensuring that workers are protected from hazardous exposure.

- Data Collection and Analysis Many robotic welding systems come equipped with advanced sensors and data collection capabilities. This allows manufacturers to monitor performance in real time, identify inefficiencies, and make data-driven decisions to optimize their processes continually.

The authoritative impact of automated spray coating systems cannot be overstated. Industries across automotive, aerospace, electronics, and construction have come to rely on these systems to meet their stringent quality and aesthetic standards. Reports and studies by industry leaders consistently point to the substantial improvements in product durability and finish quality achieved through automation. For instance, in the automotive industry, these systems have revolutionized paint applications, ensuring vehicles not only look pristine but also have enhanced protection against environmental factors.

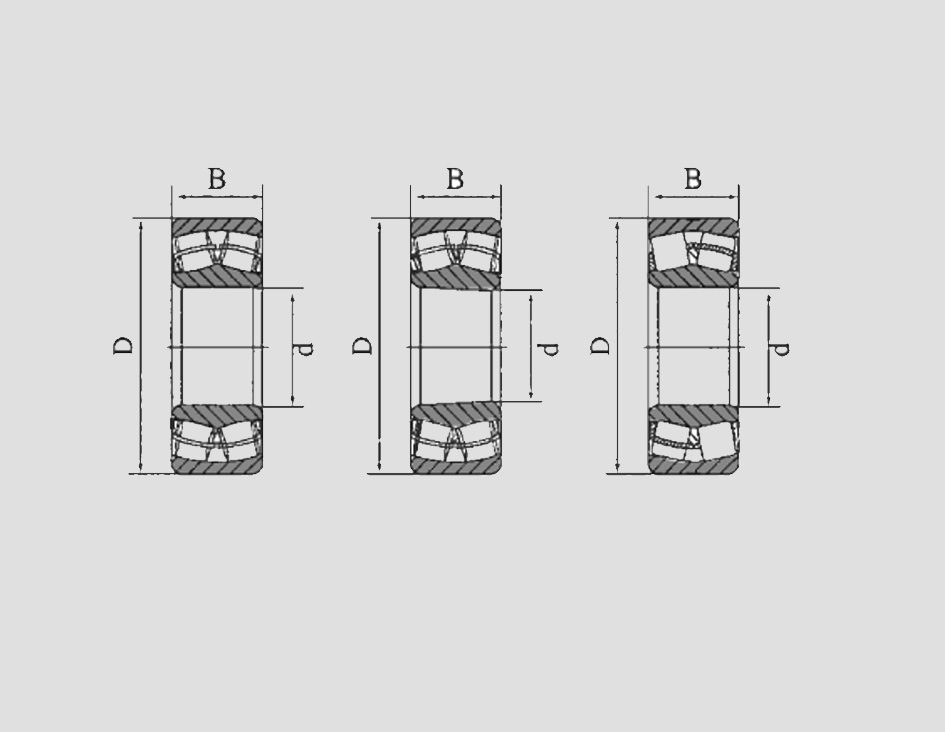

Therefore, the 30205 bearing size represents a balance between these extremes, offering a solution that is robust yet efficient Therefore, the 30205 bearing size represents a balance between these extremes, offering a solution that is robust yet efficient

Therefore, the 30205 bearing size represents a balance between these extremes, offering a solution that is robust yet efficient Therefore, the 30205 bearing size represents a balance between these extremes, offering a solution that is robust yet efficient

With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating

With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating They are particularly useful in scenarios requiring high concentricity, such as in spindles and turbines They are particularly useful in scenarios requiring high concentricity, such as in spindles and turbines

They are particularly useful in scenarios requiring high concentricity, such as in spindles and turbines They are particularly useful in scenarios requiring high concentricity, such as in spindles and turbines

Comment area