- Top: 1Step on: 6912

solutions de manutention de conteneurs

People involved | Date:2025-08-14 04:30:46

Related articles

Moreover, the advent of automation has transformed container handling. Automated guided vehicles (AGVs) are increasingly being utilized in ports and warehouses, offering a more efficient and safer alternative to traditional methods. These vehicles can operate around the clock, reducing labor costs and improving precision in container handling. The use of automation also mitigates the risk of human error, enhancing workplace safety—a crucial factor in environments where heavy equipment is in operation.

Project Description

Hệ thống Sơn Tự Động Giải Pháp Tiên Tiến Cho Ngành Công Nghiệp

Implementing the Last Container Lyft is not without its challenges. Infrastructure plays a crucial role in the successful integration of this logistics model. Significant investments are needed to develop charging stations for electric vehicles, establish drone delivery hubs, and enhance rail networks. Furthermore, regulatory frameworks must adapt to accommodate new technologies and ensure safety in urban environments. Collaboration between private companies, governments, and communities will be essential to navigate these challenges effectively.

4. Reduced Material Waste By providing accurate cuts, H-beam cutting machines help minimize material waste. This efficiency not only saves costs but also supports sustainable practices in the industry by reducing excess scrap.

The precision of automatic spray painting robots eliminates human error and minimizes material waste. Additionally, they can handle a variety of paints and finishes, making them a versatile choice for industries ranging from electronics to heavy machinery. This adaptability ensures that every product meets the highest standards of quality.

- - Retail Facilitate stock replenishment and storage in warehouses before distribution to retail outlets.

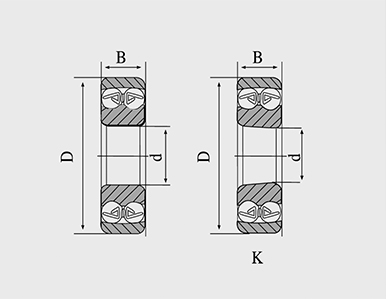

For instance, in wind turbines, where the rotor blades generate significant thrust during operation, these bearings ensure stable rotation and prevent potential damage to the turbine assembly For instance, in wind turbines, where the rotor blades generate significant thrust during operation, these bearings ensure stable rotation and prevent potential damage to the turbine assembly

For instance, in wind turbines, where the rotor blades generate significant thrust during operation, these bearings ensure stable rotation and prevent potential damage to the turbine assembly For instance, in wind turbines, where the rotor blades generate significant thrust during operation, these bearings ensure stable rotation and prevent potential damage to the turbine assembly The bearing's ability to handle heavy loads and high speeds also makes it ideal for use in wind turbines and other renewable energy technologies, contributing to the global effort towards sustainable energy solutions The bearing's ability to handle heavy loads and high speeds also makes it ideal for use in wind turbines and other renewable energy technologies, contributing to the global effort towards sustainable energy solutions

The bearing's ability to handle heavy loads and high speeds also makes it ideal for use in wind turbines and other renewable energy technologies, contributing to the global effort towards sustainable energy solutions The bearing's ability to handle heavy loads and high speeds also makes it ideal for use in wind turbines and other renewable energy technologies, contributing to the global effort towards sustainable energy solutions

For this bearing, the width is 7 mm For this bearing, the width is 7 mm

For this bearing, the width is 7 mm For this bearing, the width is 7 mm

Comment area