- Top: 9797Step on: 62

Shijiazhuang TangChao Metal flower plant stakes

People involved | Date:2025-08-14 17:42:23

Related articles

Conclusion

Welding fume and dust collectors are engineered to capture airborne contaminants. These systems typically utilize a combination of filtration and airflow management techniques.

5. Space Efficiency Many models are designed to have a small footprint, making them suitable for use in tight spaces. This feature not only maximizes workspace utilization but also allows for maneuverability in congested areas.

4. Specialty Rods Specialty rods, including those for aluminum or high-temperature applications, cater to specific needs. Aluminum rods are designed for welding aluminum and its alloys, and high-temperature rods are used in situations that require heat resistance.

In conclusion, the automatic spray coating machine exemplifies the seamless integration of technology and industry needs. It stands as a testament to modern engineering, offering unrivaled efficiency, precision, and adaptability. By investing in such equipment, businesses not only boost their operational capabilities but also align with industry standards of sustainability and quality. The combination of experience, expertise, authority, and trustworthiness makes the automatic spray coating machine a pivotal asset in any production line.

1. Spray Gun The heart of the machine, designed to atomize the coating material and deliver it smoothly.

- .

Advantages of Robotic Welding Ventilation

ISO container surveys play a critical role in the management of shipping assets. These surveys provide an in-depth assessment of containers, verifying their condition and compliance with safety standards. This process not only ensures the safety of the cargo but also protects the interests of shipping companies, freight forwarders, and their clients.

The Evolution of Painting Technology

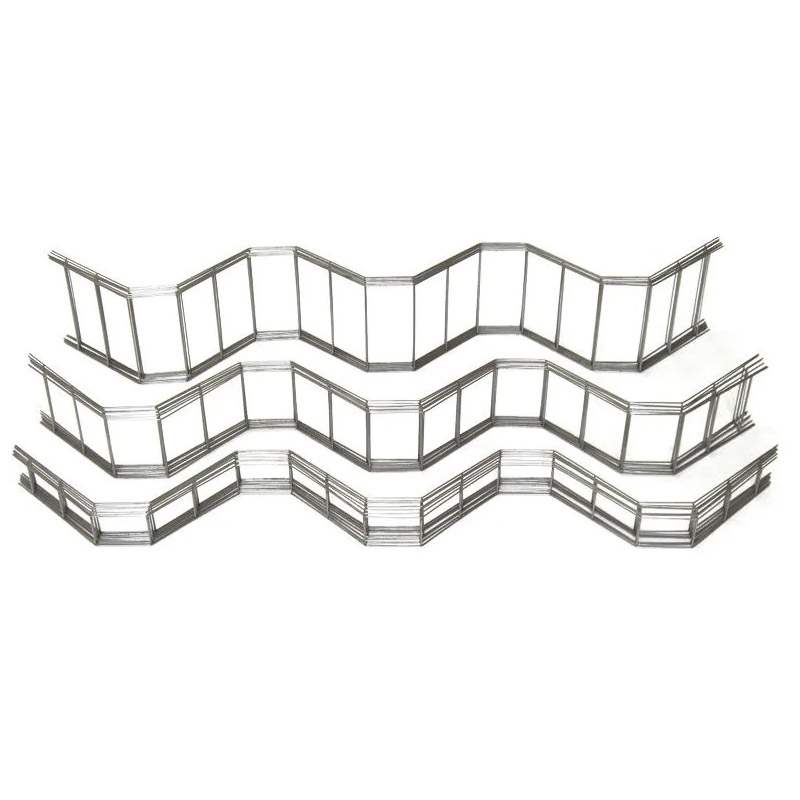

Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points

Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points

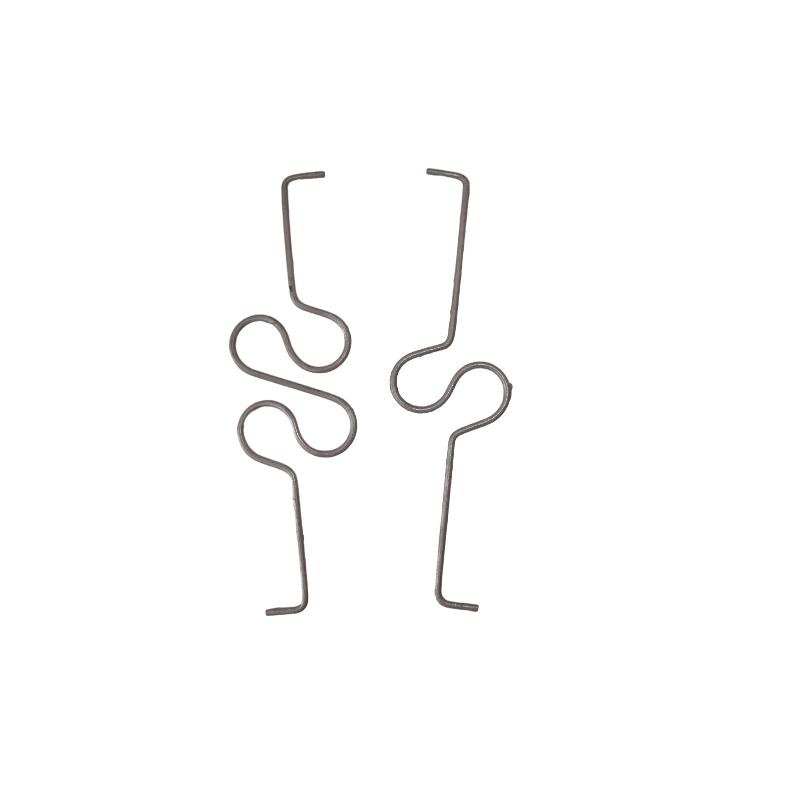

Their versatility extends beyond mere compression; they can also serve as tension or torsion springs depending on their installation and the direction of the force applied to them Their versatility extends beyond mere compression; they can also serve as tension or torsion springs depending on their installation and the direction of the force applied to them

Their versatility extends beyond mere compression; they can also serve as tension or torsion springs depending on their installation and the direction of the force applied to them Their versatility extends beyond mere compression; they can also serve as tension or torsion springs depending on their installation and the direction of the force applied to them By incorporating sensors that detect environmental changes or animal activity, farmers can receive real-time data on their mobile devices By incorporating sensors that detect environmental changes or animal activity, farmers can receive real-time data on their mobile devices

By incorporating sensors that detect environmental changes or animal activity, farmers can receive real-time data on their mobile devices By incorporating sensors that detect environmental changes or animal activity, farmers can receive real-time data on their mobile devices

Comment area