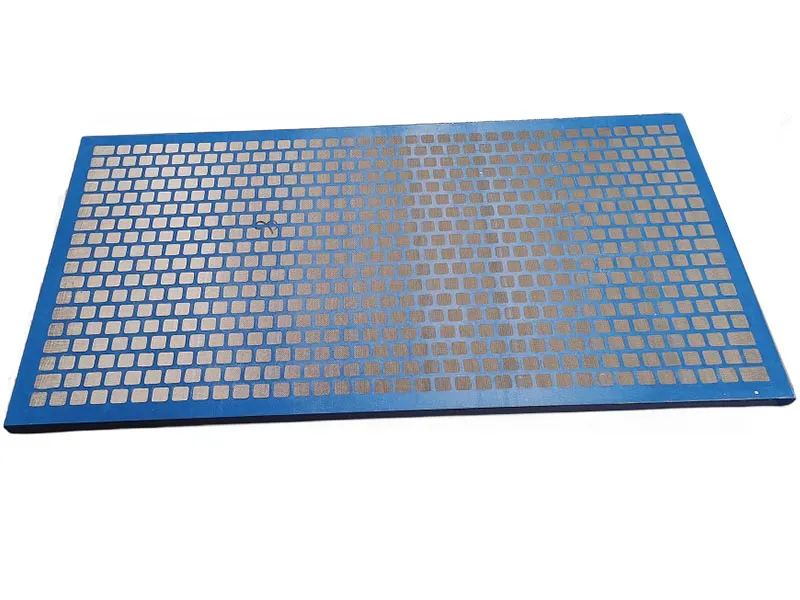

- Top: 8Step on: 855

stainless steel render corner bead

People involved | Date:2025-08-14 18:49:57

Related articles

Enhancing Visibility and Tracking

Container lifting machines have undoubtedly become indispensable tools in the logistics sector, helping to move goods more efficiently and securely across the globe.

Welding is a vital process in various industries, from construction to automotive manufacturing. While it is an essential technique for joining materials, it also poses significant health risks to workers due to the fumes and gases produced during the process. This is where air extractors come into play. Air extractors, or fume extraction systems, are an integral part of maintaining a safe working environment for welders. This article will explore the significance of air extractors in welding, their functionality, and the benefits they provide.

How Do They Work?

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States have established permissible exposure limits (PELs) for various welding fumes. Compliance is mandatory, and employers are responsible for implementing control measures, including the installation of effective fume collectors. Regular monitoring of air quality and maintenance of the dust collection systems are critical components of a comprehensive safety program.

In the fast-paced world of logistics and shipping, efficiency and precision are paramount. One of the key players that facilitate the smooth movement of goods, particularly in managing shipping containers, is the forklift. These versatile machines are integral to the transportation and delivery of containers, ensuring that the goods reach their destinations safely and on time.

- Certification and Compliance Ensure that the manufacturer complies with relevant industry standards and certifications, such as ISO or environmental regulations, which can affect your operations.

Comment area