- Top: 14Step on: 49782

roof cool coat walmart

People involved | Date:2025-08-14 10:53:29

Related articles

Unit of Smoke Extraction An Essential Component for Indoor Air Quality

When metals are fused together through welding, high temperatures vaporize the metal, generating fumes that are often hazardous to human health. Common materials involved in welding, such as mild steel, stainless steel, and aluminum, release various toxic substances, including manganese, lead, and chromium. Prolonged exposure to these fumes can result in conditions such as “metal fume fever,” chronic bronchitis, reduced lung function, and even more severe illnesses like cancer.

- Filtration Efficiency The extractor should have high-efficiency filters capable of capturing fine particles and fumes effectively. HEPA filters are often ideal for this purpose.

- - Cost Reduction While the initial investment may be substantial, the reduction in labor costs and material waste will lead to lower overall operational expenses.

- 2. Improving Quality To ensure a uniform application of paint with minimal oversight, resulting in higher-quality finishes and fewer defects.

Features of Robotic Welding Arms

Don’t let outdated painting methods slow down your productivity. Embrace the future of painting technology with Yeed Tech Co., Ltd., where quality meets efficiency!

En conclusión, la automatización del sprayfärg está revolucionando la manera en que pintamos y acabamos superficies en múltiples industrias. Con sus numerosas ventajas en eficiencia, precisión y calidad, así como su potencial para impactar positivamente en el medio ambiente, es evidente que esta tecnología ha llegado para quedarse. Mientras las empresas continúan adaptándose y evolucionando, el futuro del sprayfärg promete ser emocionante y lleno de posibilidades creativas. La innovación está en el aire, y está preparado para cambiar la forma en que vemos y utilizamos el color en nuestras vidas.

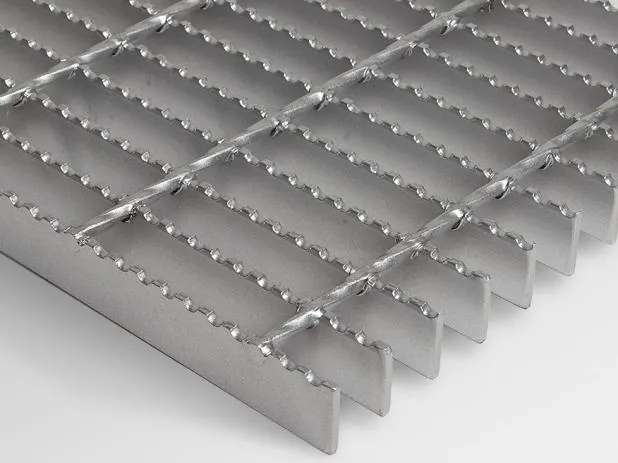

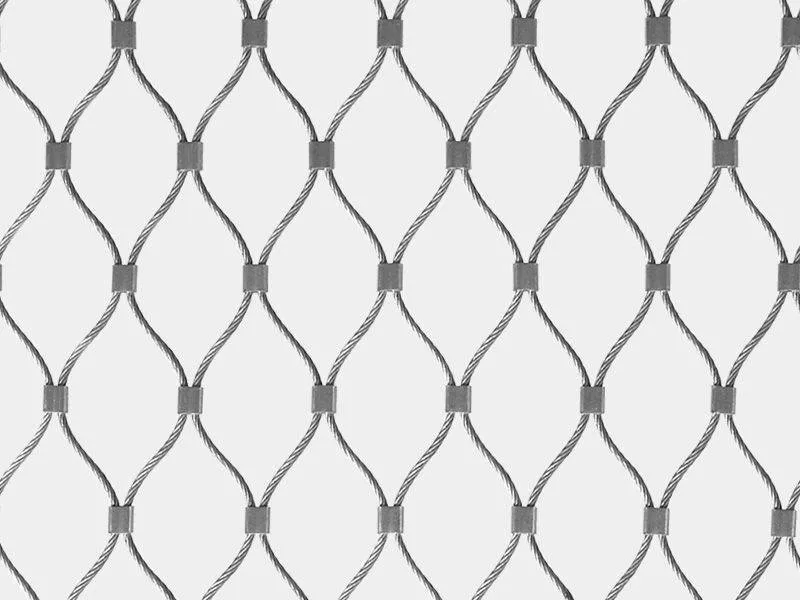

Applications of Steel Floor Systems

Comment area