- Top: 783Step on: 7973

Hebei Chida ducting for roof mounted evaporative cooler leakage

People involved | Date:2025-08-15 02:16:41

Related articles

- 4. Deployment Once the system meets all standards, we will proceed with installing the equipment in the designated production areas.

As industries continue to prioritize efficiency and precision in production processes, the implementation of automated systems is becoming increasingly essential. One such innovation is the automatic paint spraying equipment, which streamlines painting applications, enhances quality, and reduces labor costs. This project proposal outlines the development and implementation of an advanced automatic paint spraying system tailored for various industrial needs.

The journey of an automatic paint dispenser begins with its design – a masterpiece of engineering that caters to both large-scale industrial needs and small-scale personal projects. These machines employ advanced mechanisms that accurately blend pigments to achieve the desired shade, ensuring uniformity and reducing the risk of human error. This precision is particularly crucial when dealing with complex color schemes, where even a minor deviation can lead to unsatisfactory outcomes.

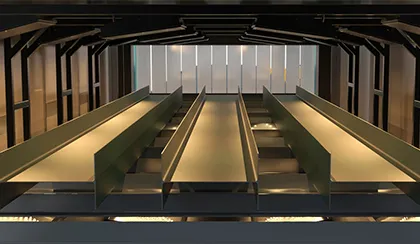

Steel structure painting requires more than just aesthetic appeal—it plays a critical role in protecting components from corrosion and environmental damage. Automatic spray painting systems excel in delivering high-quality finishes, ensuring that every layer of paint adheres perfectly to the surface.

Moreover, training employees on the importance of using fume extraction systems and adhering to safety protocols is vital. Awareness about the potential health hazards and the correct usage of equipment can significantly contribute to a safer working environment.

Cost-efficiency is a critical factor in any manufacturing operation, and an automatic spray paint booth offers significant savings in several ways. First, the automated nature of these systems reduces the need for skilled labor, lowering operational costs. Second, the precision of automatic spray painting minimizes paint wastage, cutting down on material expenses.

In terms of expertise, manufacturers of automatic paint spraying equipment continually innovate to enhance machine performance and user experience. Recent advancements include the integration of artificial intelligence (AI) to further automate settings, learning from previous tasks to optimize future operations. This technological proficiency has attracted endorsements from industry leaders, further cementing the authority and credibility of these machines. Businesses utilizing this cutting-edge equipment report a decrease in downtime and maintenance costs, showcasing the reliability and long-term value of these investments.

automatic paint spraying equipment- .

Comment area