- Top: 72824Step on: 97

owens corning cool roof data sheet

People involved | Date:2025-08-16 10:50:39

Related articles

Container Lifting Equipment Ensuring Safety and Efficiency in Cargo Handling

The Importance of Welding Fume Management

- Experience and Reputation Research the manufacturer’s track record. Look for companies with a long history and positive reviews in the industry.

1. Fume Extractors These units are specifically designed to capture welding fumes at the source before they can disperse into the surrounding air. Fume extractors usually consist of a flexible arm with extraction nozzles, which can be positioned close to the welding area. They filter out harmful particles and circulate clean air back into the workspace.

Moreover, maintaining a clean working environment improves visibility and safety. Inadequate ventilation can lead to the accumulation of smoke, making it difficult for welders to see their work and increasing the likelihood of accidents. By integrating exhaust arms into welding setups, companies can create a safer and more efficient workspace.

Automatic spray painting systems with conveyors further enhance safety by creating a physical separation between workers and hazardous operations. With automated equipment handling the painting process, employees can focus on other tasks in a safer environment. This shift not only reduces health risks but also boosts overall morale and job satisfaction.

Why Choose Yeed Tech Co., Ltd. for Your Welding Fume Extraction Needs?

Types of Ventilation Systems for Robotic Welding

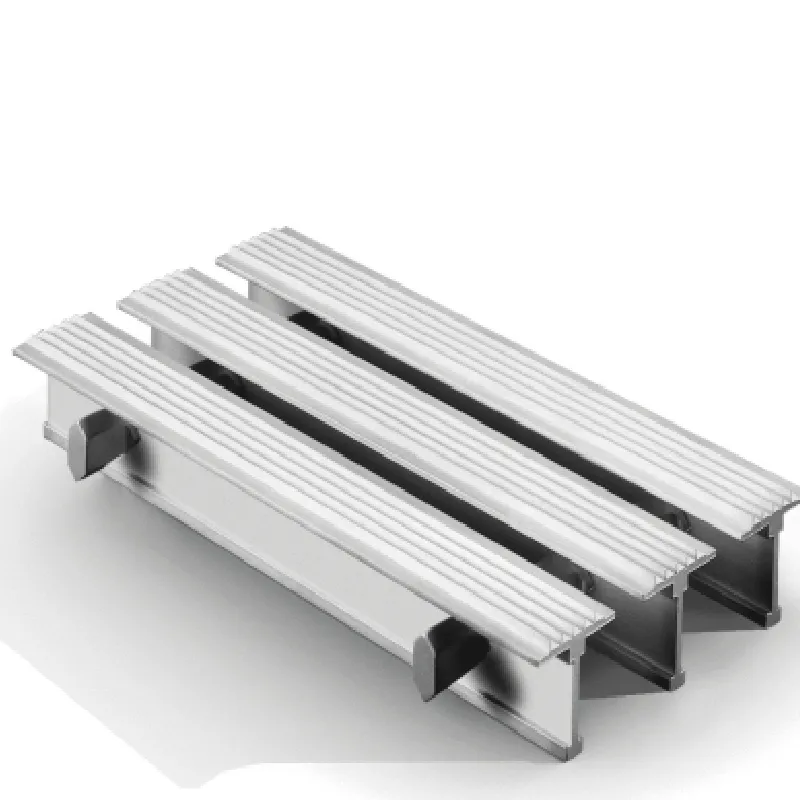

The importance of stacking bars cannot be overstated in shipping operations. The marine shipping industry has witnessed significant advancements in container shipping efficiency, with vessels increasingly carrying hundreds, if not thousands, of containers per voyage. This compact stacking of containers on board reduces logistical costs and optimizes space; however, it also raises concerns about the safety and integrity of the stacked units.

Comment area