- Top: 2Step on: 715

Hebei Chida cool white roof

People involved | Date:2025-08-14 14:59:43

Related articles

Welding is an essential industrial process employed in various sectors such as construction, manufacturing, and repair. Despite its importance, it poses significant health risks for welders due to the harmful fumes generated during the operation. Welding fumes consist of a complex mixture of metal oxides, silicates, and other hazardous compounds, which can cause respiratory issues and long-term health problems. Therefore, implementing an effective welding fume extraction system is crucial for maintaining a safe working environment.

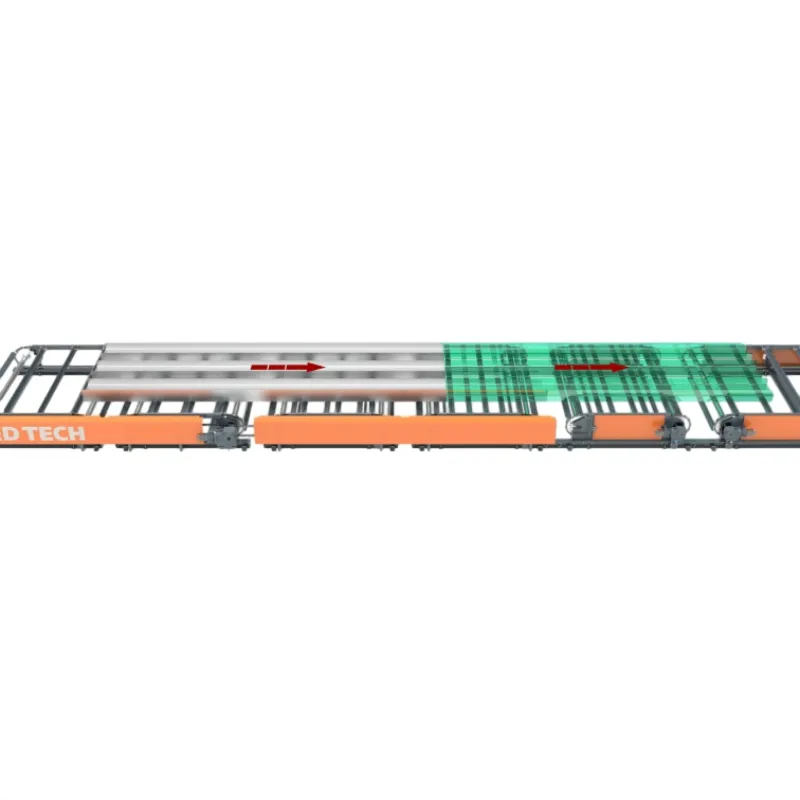

As industries continue to evolve, the need for advanced steel structure painting solutions becomes increasingly evident. Automatic spray painting machines address these demands by offering unparalleled precision, efficiency, and adaptability.

However, the effectiveness of smoke collectors is influenced by various factors, including the type of technology used, maintenance practices, and the specific pollutants being targeted. Continuous innovation in this field is essential to enhance the efficiency of smoke collectors and to address emerging pollution challenges. Research and development efforts are focused on creating more advanced filtration materials and systems that can better capture a broader range of pollutants.

Moreover, training employees on the importance of using fume extraction systems and adhering to safety protocols is vital. Awareness about the potential health hazards and the correct usage of equipment can significantly contribute to a safer working environment.

- Multiple Entry Points The design can easily accommodate multiple entry points, increasing convenience and traffic flow.

Welding is a critical process across various industries, essential for constructing metals and creating structures that are robust and enduring. However, the process generates significant amounts of smoke, gases, and fumes, which can pose serious health risks to welders and those in proximity. This is where svetsventilationsutrustning, or welding ventilation equipment, comes into play. This article delves into the importance of welding ventilation systems, their types, and the best practices to ensure a safe working environment.

A wall-mounted welding exhaust fan is a ventilation device specifically designed to remove contaminated air from welding areas. These fans are typically installed in a wall or window and are strategically positioned to capture harmful fumes and gases generated during welding operations. Most wall-mounted fans are equipped with high-capacity motors and durable construction to withstand the harsh conditions of welding environments.

- 3. Conveyor Belts Many machines integrate conveyor systems to move items through the coating process automatically, ensuring efficiency and consistency.

Comment area