- Top: 7Step on: 486

Shijiazhuang TangChao Metal plastic sign holders

People involved | Date:2025-08-14 17:46:34

Related articles

3. Cast Iron Rods Cast iron rods are specifically formulated for welding cast iron components. They are essential in repairs where cast iron pots, pipes, or machinery need to be joined or mended.

- - Operational Efficiency Well-maintained containers reduce the likelihood of unplanned downtime, thereby enhancing overall shipping efficiency.

- 2. Weight Capacity The markings often include information about the maximum load capacity of the container. This helps operators understand how much weight can be safely lifted and transported, reducing the risk of accidents during handling.

- Experience and Reputation Research the manufacturer’s track record. Look for companies with a long history and positive reviews in the industry.

في عالمنا اليوم، حيث تزداد الوعي بمخاطر التدخين والتلوث الهوائي، يعد نظام mobil rökutsugsenhet خطوة نحو تحسين نوعية الحياة والصحة العامة. من خلال توفير بيئة أكثر نقاءً وآمنة، يمكن أن يسهم هذا الجهاز في تقليل آثار التدخين السلبي، مما يجعله خيارًا مثاليًا لجميع المعنيين. إن الاستثمار في مثل هذه الأنظمة هو استثمار في صحة وسلامة المجتمع ككل.

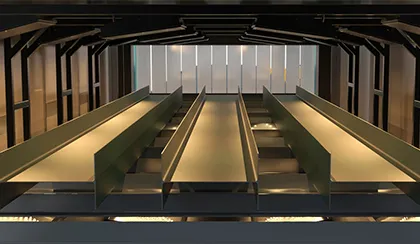

At the heart of these machines is their ability to offer a consistent and high-quality finish, a key differentiator from manual painting techniques. The integration of advanced robotics and control systems ensures that paint is applied uniformly, reducing the incidence of human error and enhancing the overall aesthetic appeal of the product. With automatic spray painting machines, manufacturers can achieve a flawless finish that meets stringent industry standards and consumer expectations.

Automation is a key trend in the logistics sector, and container transportation control equipment embodies this shift. Automated loading and unloading systems significantly reduce the manual labor required in handling containers. By utilizing cranes, conveyor belts, and automated guided vehicles (AGVs), companies can enhance the speed and accuracy of loading operations, which is critical in meeting tight shipping schedules.

From a practical perspective, adopting automatic spray painting machines significantly enhances production throughput. The machines can operate continuously with minimal downtime for maintenance, unlike manual labor which is subject to fatigue and inconsistency. This scalability allows businesses to meet rising demands without compromising on quality or delivery timelines.

Precision and Consistency with Automatic Paint Sprayer Machines

Comment area