- Top: 93512Step on: 2329

linia do malowania natryskowego

People involved | Date:2025-08-14 03:57:54

Related articles

5. Operational Flexibility Portable fume extractors provide flexibility in welding operations. They can be used in various locations and settings, making them ideal for mobile welding jobs where fixed systems may not be practical.

The Weight of the Container A Journey into Strength and Resilience

- Cost vs. Value While it may be tempting to choose the cheapest option available, consider the overall value. Investing in high-quality equipment can save costs in the long run through increased efficiency and lower maintenance.

In the world of logistics and heavy machinery, the manipulation of shipping containers has become an essential component for efficient supply chain management. Among the various types of material handling equipment, telescopic container handlers have emerged as a versatile and effective solution for managing container operations, especially in ports, logistics hubs, and warehouses. This article delves into what telescopic container handlers are, their functionality, and the numerous advantages they offer in container management.

In the fast-paced world of global trade and shipping, efficiency is key to ensuring timely deliveries and reducing operational costs. One of the most important innovations in modern logistics is the development of container lifting machines, which have dramatically transformed how cargo is handled at ports and distribution centers around the world.

In recent years, the demand for portable welding solutions has surged across various industries, including construction, manufacturing, and automotive repair. The need for flexibility and efficiency in welding processes has led to significant advancements in portable welding technology, enabling professionals to perform high-quality welds on-site without the limitations of traditional welding setups.

- Ease of Use and Maintenance Choose a portable extractor that is user-friendly and easy to maintain. Systems with intuitive designs and easy access to filters and components will save time and effort.

As industries become more aware of their environmental impact, the adoption of automatic spray painting technology also lends itself to more responsible practices. Many modern systems are designed to be eco-friendly, utilizing advanced filtration and ventilation systems to limit the emission of volatile organic compounds (VOCs) and other harmful substances. Furthermore, precise paint application reduces overspray and waste, contributing to more sustainable production processes.

There are several types of svetsventilationsutrustning available, each designed to suit different welding environments and needs

The welding process releases fumes containing various harmful substances, including metallic oxides, silicates, and gases like ozone and nitrogen dioxide. Prolonged exposure to these fumes can pose serious health risks to welders, including respiratory issues, irritation of the eyes and throat, and long-term conditions such as lung cancer. Using an exhaust arm can significantly reduce these risks by ensuring that harmful fumes are promptly captured and removed from the work area.

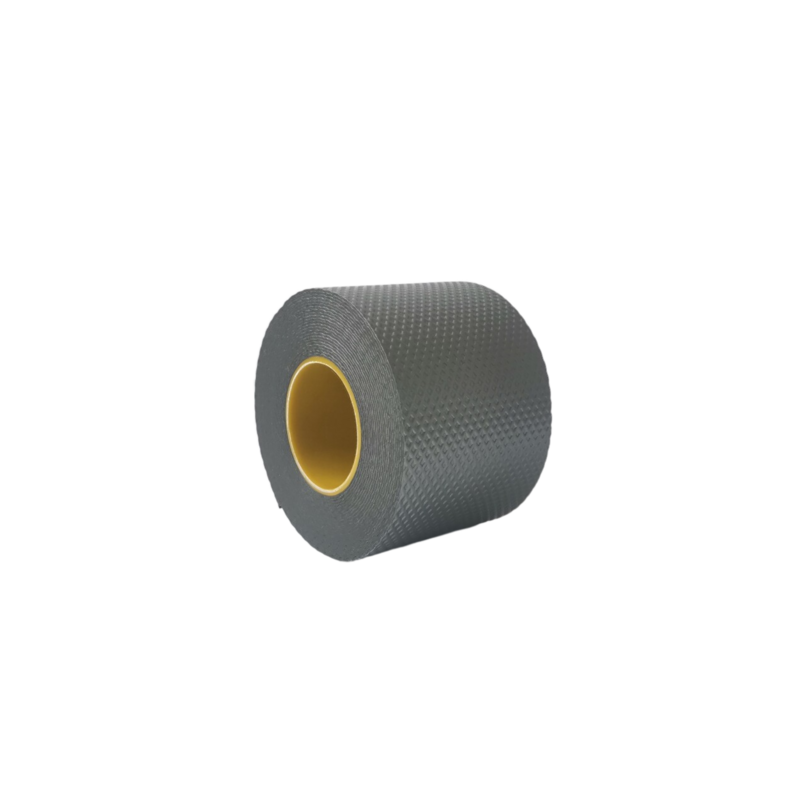

Its adhesive is specifically formulated to create a strong bond that withstands vibrations, impacts, and temperature fluctuations Its adhesive is specifically formulated to create a strong bond that withstands vibrations, impacts, and temperature fluctuations

Its adhesive is specifically formulated to create a strong bond that withstands vibrations, impacts, and temperature fluctuations Its adhesive is specifically formulated to create a strong bond that withstands vibrations, impacts, and temperature fluctuations It allows you to see what is underneath the tape, making it easier to accurately place and align It allows you to see what is underneath the tape, making it easier to accurately place and align

It allows you to see what is underneath the tape, making it easier to accurately place and align It allows you to see what is underneath the tape, making it easier to accurately place and align When applied to clean, dry surfaces, the butyl rubber adheres tenaciously, creating a strong, seamless bond that resists peeling or cracking When applied to clean, dry surfaces, the butyl rubber adheres tenaciously, creating a strong, seamless bond that resists peeling or cracking

When applied to clean, dry surfaces, the butyl rubber adheres tenaciously, creating a strong, seamless bond that resists peeling or cracking When applied to clean, dry surfaces, the butyl rubber adheres tenaciously, creating a strong, seamless bond that resists peeling or cracking

Comment area