- Top: 8157Step on: 474

filtro de fumos de soldagem

People involved | Date:2025-08-14 09:27:04

Related articles

Our small portable fume extractor is engineered for maximum efficiency, featuring easy setup and operation. Its user-friendly design allows you to quickly relocate the unit as needed, ensuring that you have effective fume extraction wherever you work. This versatility makes our small portable fume extractor a valuable asset for anyone in the welding and metalworking industries.

In conclusion, automatic spray coating machines are revolutionizing manufacturing practices across various sectors, delivering unparalleled efficiency, quality, and safety. As industries continue to innovate and adapt to new technologies, these machines will remain at the forefront, driving productivity and sustainability in the manufacturing arena.

The foundation of an efficient automatic spraying line lies in its structural integrity. Steel structures play a crucial role in providing the durability and stability required to support these advanced systems. From the framework of the automatic spray paint booth to the conveyors that transport materials, steel structures ensure the smooth operation of the entire line.

Invest in your wellbeing and the health of your team with our reliable welding fume extraction solutions. Together, we can ensure a safer future for your welding operations!

- Warehousing and Logistics In warehouses, the Górny Podnośnik is frequently used for stacking and unstacking products, improving warehouse operations while enhancing safety for workers handling heavy loads.

A major advantage of automatic paint sprayer machines is their ability to deliver uniform coatings across all surfaces. Unlike manual methods, these machines minimize human error, resulting in smoother finishes and reduced rework.

- .

Applications of Steel Floor Systems

As the manufacturing sector continues to embrace robotic welding, ensuring worker safety and air quality becomes increasingly important. Implementing a tailored ventilation system not only secures the health of workers but also enhances overall productivity and compliance with health regulations. By investing in robotic welding ventilation, industries can create safer work environments, leading to a more sustainable and efficient manufacturing process. The future of robotic welding lies not only in technological advancements but also in our commitment to protecting the workers who operate these sophisticated systems.

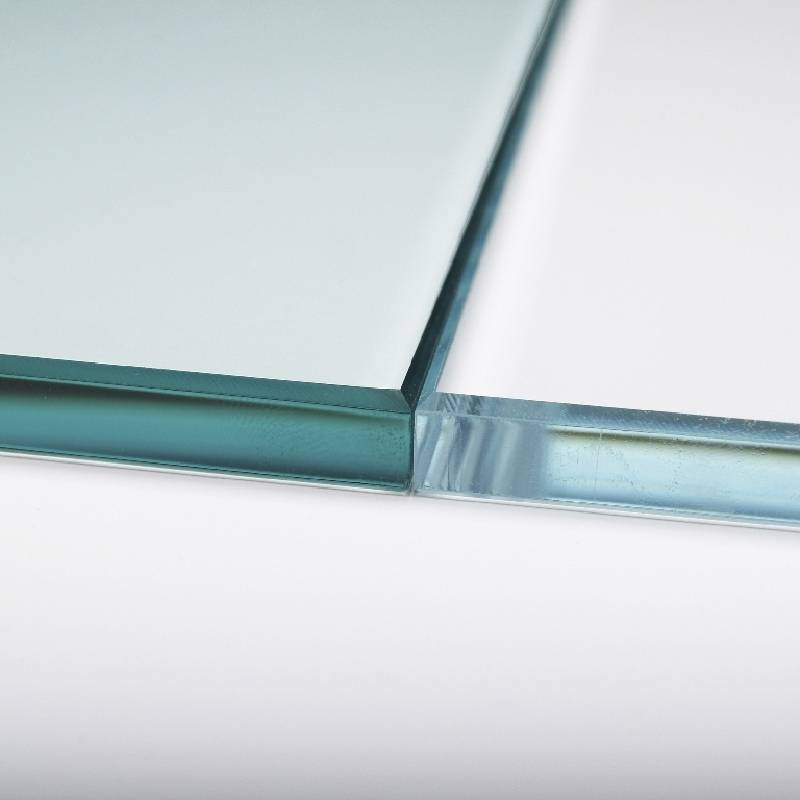

The frosted finish helps to conceal fingerprints and smudges, making them a practical choice for high-traffic areas The frosted finish helps to conceal fingerprints and smudges, making them a practical choice for high-traffic areas

The frosted finish helps to conceal fingerprints and smudges, making them a practical choice for high-traffic areas The frosted finish helps to conceal fingerprints and smudges, making them a practical choice for high-traffic areas

It also ensures privacy while maintaining natural light flow, creating a visually appealing and healthy living or working environment It also ensures privacy while maintaining natural light flow, creating a visually appealing and healthy living or working environment

It also ensures privacy while maintaining natural light flow, creating a visually appealing and healthy living or working environment It also ensures privacy while maintaining natural light flow, creating a visually appealing and healthy living or working environment It reflects not only the physical surroundings but also the personality of the space and those who inhabit it It reflects not only the physical surroundings but also the personality of the space and those who inhabit it

It reflects not only the physical surroundings but also the personality of the space and those who inhabit it It reflects not only the physical surroundings but also the personality of the space and those who inhabit it

Comment area