- Top: 89Step on: 3

danley dowel cradle

People involved | Date:2025-08-14 04:57:57

Related articles

Our inventory features a wide variety of container handling equipment designed to accommodate various capacities and operational needs. Whether you are a small business or a large logistics provider, we have the solutions to meet your specific requirements.

In summary, the decision to integrate an automatic spray coating machine into your production line enhances both the technical quality and operational efficiency of your manufacturing processes. It represents a confluence of innovation and practicality, offering tangible benefits in productivity, cost savings, and safety. Organizations that adopt this technology demonstrate a commitment to maintaining quality standards and operational excellence. Embracing this technology is not just an operational upgrade; it is a strategic move towards sustained competitiveness in a complex marketplace.

The use of forklift containers comes with several advantages

Importance of Efficient Container Loading

Key Components of an ISO Container Survey

Factors Affecting Container Lifting Machine Prices

3. Technical Support and Training Implementing new spray coating equipment often requires training. A good manufacturer will provide comprehensive training programs and technical support to help clients maximize their investment and ensure proper operation.

In conclusion, the unit of smoke extraction is an indispensable element for ensuring indoor air quality across various sectors. By effectively removing smoke and harmful pollutants, these systems safeguard the health of occupants and protect the integrity of the environment. As technology continues to advance, the integration of intelligent systems into smoke extraction units promises even greater efficiency and effectiveness, making them an essential investment for any facility aiming to enhance its air quality management. Adopting these systems is not just a regulatory compliance measure but a commitment to creating safer and healthier spaces for all.

4. Cost-Effectiveness While the initial investment in automatic spray coating machinery can be significant, the long-term savings are considerable. Reduced labor costs, lower material waste, and enhanced productivity contribute to a more favorable return on investment.

Moreover, automatic spray painting machines are at the forefront of sustainability efforts in manufacturing. They are engineered to maximize paint utilization, significantly reducing wastage. This has a dual benefit it lowers operational costs and minimizes the environmental footprint. Additionally, these machines can be equipped with advanced filtration systems that capture overspray, further mitigating environmental impact and complying with regulatory standards.

automatic spray painting machine

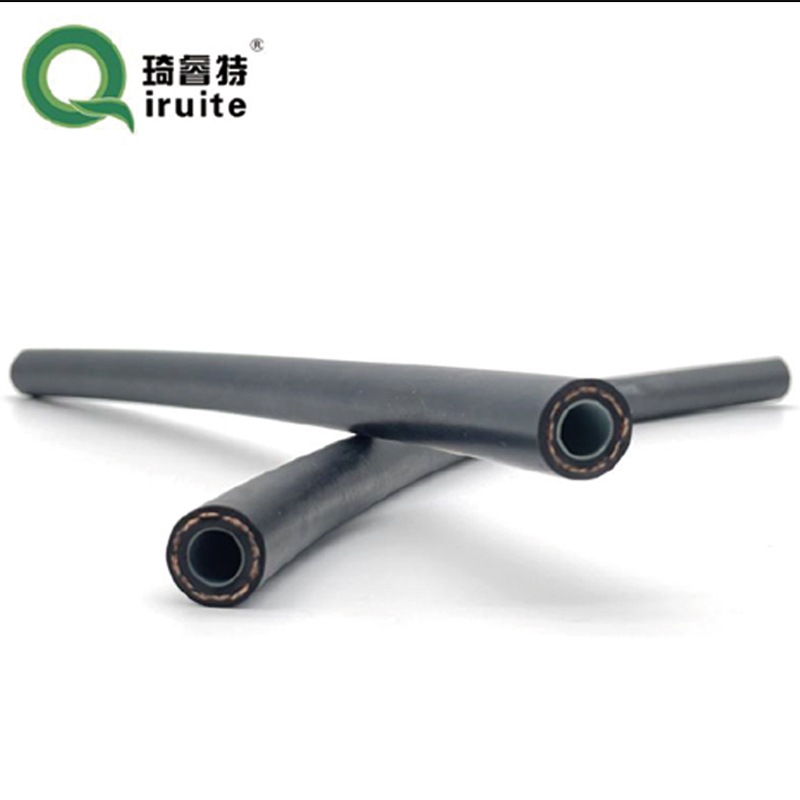

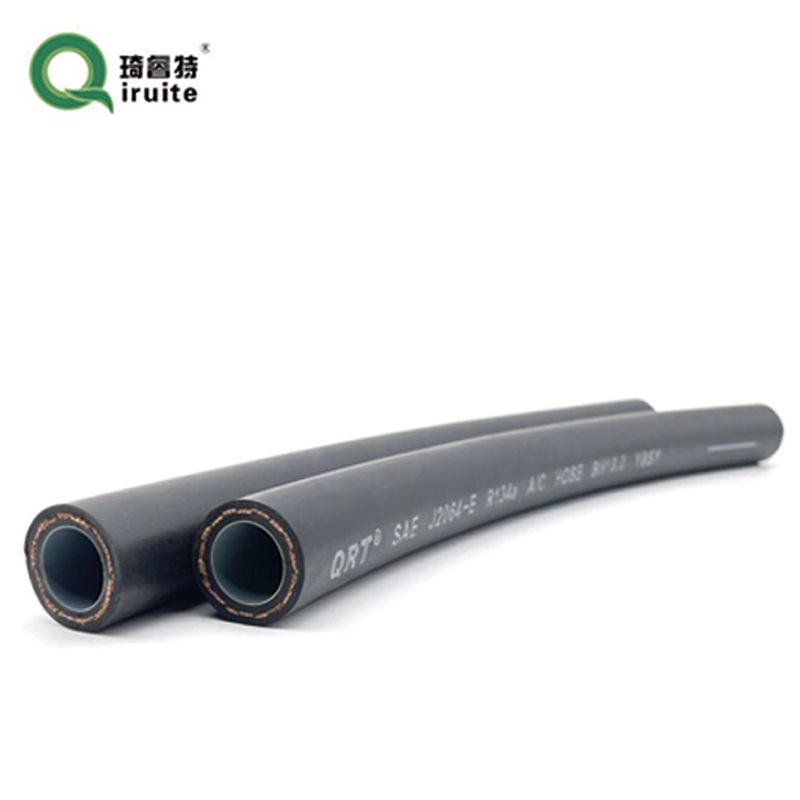

Any leakage or damage to the hose can lead to reduced power steering assistance, making the vehicle harder to steer and potentially impacting overall driving safety Any leakage or damage to the hose can lead to reduced power steering assistance, making the vehicle harder to steer and potentially impacting overall driving safety

Any leakage or damage to the hose can lead to reduced power steering assistance, making the vehicle harder to steer and potentially impacting overall driving safety Any leakage or damage to the hose can lead to reduced power steering assistance, making the vehicle harder to steer and potentially impacting overall driving safety By optimizing the gas mixture, plants can achieve higher throughput and lower costs, ultimately contributing to a more sustainable and environmentally friendly process By optimizing the gas mixture, plants can achieve higher throughput and lower costs, ultimately contributing to a more sustainable and environmentally friendly process

By optimizing the gas mixture, plants can achieve higher throughput and lower costs, ultimately contributing to a more sustainable and environmentally friendly process By optimizing the gas mixture, plants can achieve higher throughput and lower costs, ultimately contributing to a more sustainable and environmentally friendly process

Comment area