- Top: 69Step on: 28

green roof vs cool roof

People involved | Date:2025-08-16 02:40:46

Related articles

Precision and Consistency with Automatic Paint Sprayer Machines

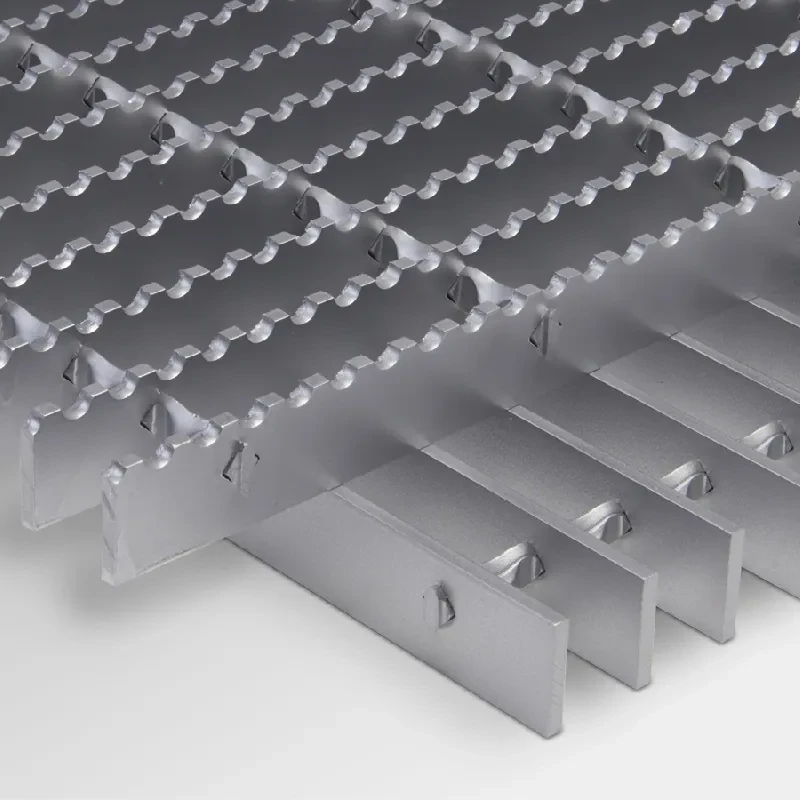

- Industrial Facilities Warehouses and manufacturing plants benefit from the heavy load-bearing capabilities of steel floors. The ability to incorporate heavy machinery without compromising structural integrity makes this a popular choice.

Enhancing Safety with Welding Extraction Systems

Automatic spray coating machines offer businesses a competitive edge by merging operational efficiency with unparalleled precision in coating applications. Their integration into production lines is not merely an upgrade in machinery but a strategic investment in overall production quality and capacity. This leap forward transcends traditional methods, enabling industries to meet the increasing demands for faster production without compromising on product quality.

Don’t let outdated painting methods slow down your productivity. Embrace the future of painting technology with Yeed Tech Co., Ltd., where quality meets efficiency!

Advantages of Steel Frame Pole Barns

- 5. Training and Support Provide comprehensive training for operators and ongoing support to ensure efficient utilization of the new system.

Environmental considerations are another important aspect of the exhaust system's function. Today’s vehicles are equipped with advanced technologies, such as catalytic converters, which convert harmful substances in the exhaust gases, like hydrocarbons and carbon monoxide, into less harmful emissions before they are released into the atmosphere. This technology is crucial for reducing air pollution and meeting increasingly stringent environmental regulations. As consumers become more conscious of their carbon footprints, the role of the exhaust system becomes even more prominent in discussions about sustainability and responsible driving.

Saldırış gazlarini yo'qotish tizimlari, umumiy maqsad sifatida, ishlab chiqarish jarayonida hosil bo'lgan zaharli moddalarni chiqarib yuborish va ishchilarni himoya qilishni maqsad qiladilar. Bu tizimlar asosan quyidagi uchta asosiy komponentni o'z ichiga oladi

For years, manual welding was the standard approach in fabrication and manufacturing. However, as demands for higher precision and faster production times have increased, many industries have begun to adopt robotic systems. Welding arms equipped with intelligent software allow for greater consistency in welds, making them ideal for projects that require high precision. With robotic systems, operators can program these machines to perform repetitive tasks with minimal error, ensuring each weld is of the highest quality.

Comment area