- Top: 5Step on: 25288

korporacja zajmująca się systemami obsługi kontenerów

People involved | Date:2025-08-14 07:22:56

Related articles

نظام تهوية متكامل لتدخين السجائر

- Centralized Systems Large industrial facilities might opt for a centralized fume extraction system, which uses ductwork to transport fumes from multiple welding stations to a central collector. This approach can effectively manage air quality across extensive manufacturing areas.

Conclusion

The introduction of automatic ink dispensers has revolutionized the printing industry, offering multiple benefits, including enhanced precision, waste reduction, and increased efficiency. As the technology continues to advance, these dispensers will play an even more critical role in meeting the demands of modern printing environments. Businesses that invest in this technology will not only improve their operational efficiency but also gain a competitive edge in an ever-evolving market. Embracing automatic ink dispensers is not just a trend; it is a strategic move towards a more efficient and sustainable future in printing.

Compliance with Safety Standards

- 3. Improve Inventory Management By organizing products within specific containers, businesses can streamline inventory tracking and retrieval processes, reducing the likelihood of misplacement.

The mobile welding fume extraction unit is designed to be easy to transport and operate, offering robust performance without compromising on safety or efficiency. This is particularly valuable in facilities with dynamic production needs, where welding stations might frequently change locations or require adjustments. Integrating a mobile fume extraction unit with welding arms is the perfect way to achieve a safer and more flexible working environment.

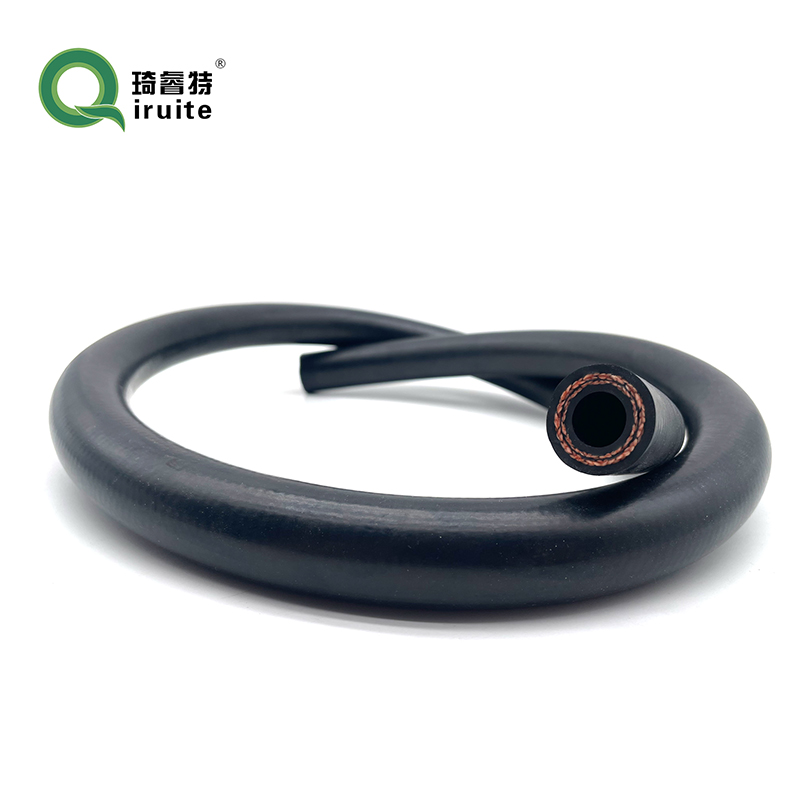

Signs of a failing hose may include difficulty in steering, a whining or squealing noise from the power steering pump, or visible leaks Signs of a failing hose may include difficulty in steering, a whining or squealing noise from the power steering pump, or visible leaks

Signs of a failing hose may include difficulty in steering, a whining or squealing noise from the power steering pump, or visible leaks Signs of a failing hose may include difficulty in steering, a whining or squealing noise from the power steering pump, or visible leaks Furthermore, the stainless steel braiding acts as a shield against external impacts, reducing the risk of damage that could lead to leaks or failure Furthermore, the stainless steel braiding acts as a shield against external impacts, reducing the risk of damage that could lead to leaks or failure

Furthermore, the stainless steel braiding acts as a shield against external impacts, reducing the risk of damage that could lead to leaks or failure Furthermore, the stainless steel braiding acts as a shield against external impacts, reducing the risk of damage that could lead to leaks or failure

The first step is to locate the power steering hose and identify any leaks or damage The first step is to locate the power steering hose and identify any leaks or damage

The first step is to locate the power steering hose and identify any leaks or damage The first step is to locate the power steering hose and identify any leaks or damage This will prevent the threads from loosening during installation This will prevent the threads from loosening during installation

This will prevent the threads from loosening during installation This will prevent the threads from loosening during installation Once the issue has been identified, the damaged section of the hose will need to be replaced Once the issue has been identified, the damaged section of the hose will need to be replaced

Once the issue has been identified, the damaged section of the hose will need to be replaced Once the issue has been identified, the damaged section of the hose will need to be replaced

Comment area