- Top: 3Step on: 2344

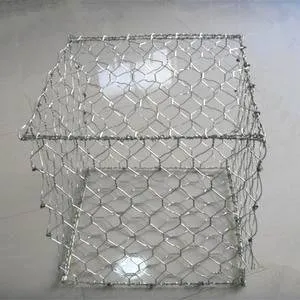

Shijiazhuang TangChao Metal h frame stakes

People involved | Date:2025-08-14 06:04:01

Related articles

The Importance of Exhaust Ventilation in Welding

How Do They Work?

In conclusion, automated spray coating systems represent a confluence of technology, expertise, and industry demand. They are not merely a tool but a catalyst for quality, efficiency, and evolution in manufacturing. Businesses adopting these systems equip themselves with a competitive edge, poised to meet the challenges of an ever-evolving industrial landscape.

The Revolution of Automatic Spray Coating Machines

Conclusion

Real-world experience further underscores the benefits of automated spray coating systems. Consider the experience of a medium-sized electronics manufacturer that incorporated automated spray coating into its production line. The transition resulted in a 30% increase in production speed and a significant reduction in material waste. Additionally, the consistency of the coating improved noticeably, reducing the defect rate by half and exponentially enhancing the final product's marketability.

The automated painting process revolutionizes production lines by reducing downtime and increasing throughput. By automating repetitive tasks, manufacturers can allocate resources more effectively and focus on innovation.

In various manufacturing and construction industries, welding processes are essential for joining metal components. However, welding activities generate hazardous fumes and dust that pose serious health risks to workers if not properly managed. Welding fume and dust collectors are critical devices designed to capture these pollutants, ensuring a safer working environment and promoting compliance with occupational health and safety regulations.

Comment area