- Top: 77211Step on: 51882

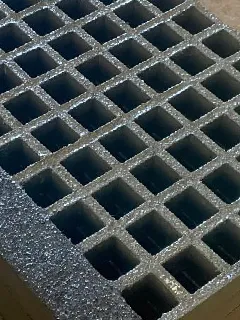

Shijiazhuang TangChao Metal 8x8 welded wire mesh

People involved | Date:2025-08-14 16:13:08

Related articles

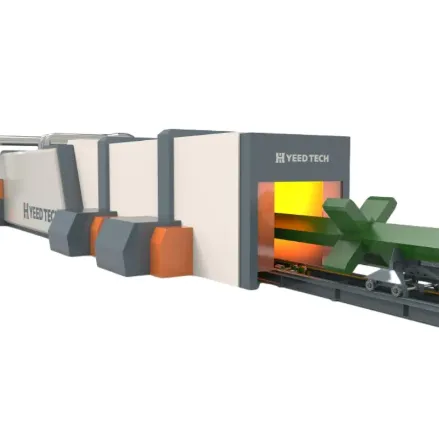

Enhancing Efficiency with Steel Structure Manufacturing Equipment

Weld smoke is an unavoidable byproduct of the welding process, but its risks can be effectively managed. By understanding its composition and health effects, and implementing robust mitigation strategies, industries can protect workers and create a safer environment. Ensuring the well-being of welders is not only a legal obligation but an ethical imperative that contributes to the overall health and productivity of the workforce. As the industry continues to evolve, so too must our commitment to worker safety in the face of potential hazards like weld smoke.

Welding fume collectors come in various designs, each tailored to specific industrial needs. Here are some common types

3. Accessibility Containers should be designed with features that facilitate easy access, such as open tops or removable sides, making it easier for workers to load and unload materials quickly.

One of the standout benefits of an automatic spraying line is its ability to boost manufacturing efficiency. Traditional manual painting methods are time-consuming and labor-intensive, often leading to inconsistent results. In contrast, automatic spray paint systems operate at high speeds and with remarkable accuracy, significantly increasing throughput.

Sustainability is a growing priority across industries, and the manufacturing sector is no exception. As companies strive to reduce their environmental footprint, tools like welding arms and advanced extraction systems play a pivotal role in achieving greener operations. Modern welding technologies minimize energy consumption, reduce waste, and ensure a safer working environment, making them essential for sustainable production. This article explores the importance of welding arms, welding fume extraction systems, and related technologies in driving eco-friendly manufacturing.

4. Reduced Material Waste By providing accurate cuts, H-beam cutting machines help minimize material waste. This efficiency not only saves costs but also supports sustainable practices in the industry by reducing excess scrap.

3. Design Flexibility Steel floor systems offer architects and engineers a high degree of design flexibility. The ability to span large distances without the need for intermediate supports opens up possibilities for innovative layouts and open floor designs. This is especially crucial in modern office buildings and shopping complexes.

Choosing the right spray coating equipment manufacturer is essential for ensuring quality, efficiency, and reliability in the coating process. A reputable manufacturer will provide advanced technologies tailored to specific industry needs, along with a range of support services, including

Comment area