- Top: 193Step on: 74

250 wall ties

People involved | Date:2025-08-14 13:28:38

Related articles

Small Welding Fume Extractor

Reducing Costs with an Automatic Spray Paint Booth

The rise of automatic paint spraying robots has marked a significant milestone in industrial painting processes. Their precision, efficiency, and ability to streamline operations while ensuring safety make them a valuable asset for manufacturers. As technology continues to advance, we can expect further enhancements in these systems, leading to even more innovative solutions in the realm of industrial painting. As industries adopt these robots, the future of manufacturing looks brighter and more efficient than ever before.

Conclusion

- Commercial Buildings High-rise office buildings often utilize steel floor systems to create open and flexible workspaces. The speed of construction and design versatility allows for rapid development.

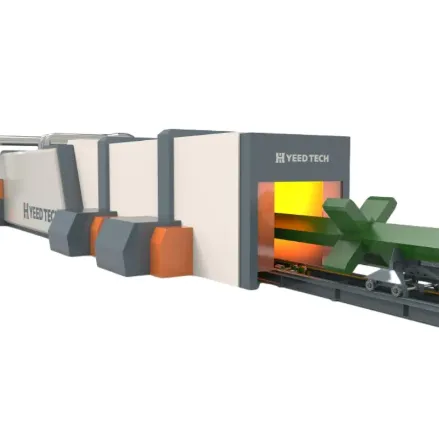

Automatic spray painting machines are engineered to offer consistent coating quality, essential in industries where uniformity and precision are paramount. Known for their ability to deliver an even layer of paint or coating across diverse surfaces, these machines ensure that no section is overpainted or undercoated, which is crucial in sectors such as automotive, aerospace, and consumer electronics. By minimizing human error, businesses can rely on superior finishes and enhanced durability of products, aligning with consumer expectations and stringent regulatory standards.

In facilities where mobility is key, mobile fume extractors are an excellent solution for capturing welding fumes while maintaining flexibility. These portable systems can be easily moved to different areas of the workshop, ensuring that even remote or hard-to-reach areas are free from hazardous smoke and particulate matter.

- - Cost Reduction While the initial investment may be substantial, the reduction in labor costs and material waste will lead to lower overall operational expenses.

Comment area