- Top: 68753Step on: 5

steel wall framing system

People involved | Date:2025-08-14 04:40:56

Related articles

Why Automatic Spray Painting Machines Are the Future

In conclusion, automatic spray painting machines deliver tangible benefits to manufacturing processes, enhancing experience through efficiency and precision. Their expertise-driven designs, established authority in large-scale operations, and the trust they build through reliable performance make them an indispensable asset. By integrating automatic spray painting machines, businesses can achieve superior product quality, reduce operational costs, and maintain competitive advantages in their respective markets.

Safety Considerations

Implementing effective ventilation in robotic welding environments offers multiple benefits

- - Cost Reduction While the initial investment may be substantial, the reduction in labor costs and material waste will lead to lower overall operational expenses.

Steel floor systems are now integral to various types of construction projects. They are commonly employed in the following applications

Hệ thống Sơn Tự Động Giải Pháp Tiên Tiến Cho Ngành Công Nghiệp

- 2. Prototype Development Create a prototype of the automatic paint spraying system, enabling initial testing and adjustments.

In conclusion, air extractors are essential for enhancing the safety and efficiency of welding operations. By effectively removing harmful fumes and improving air quality, these systems protect workers’ health, boost productivity, and help companies comply with health and safety regulations. Investing in a reliable air extraction system is not just an option; it is a necessity for any organization that values the well-being of its employees and aims for sustainable operational excellence. As the welding industry continues to evolve, the importance of air extractors will only grow, highlighting the need for ongoing innovation and improvement in fume extraction technologies.

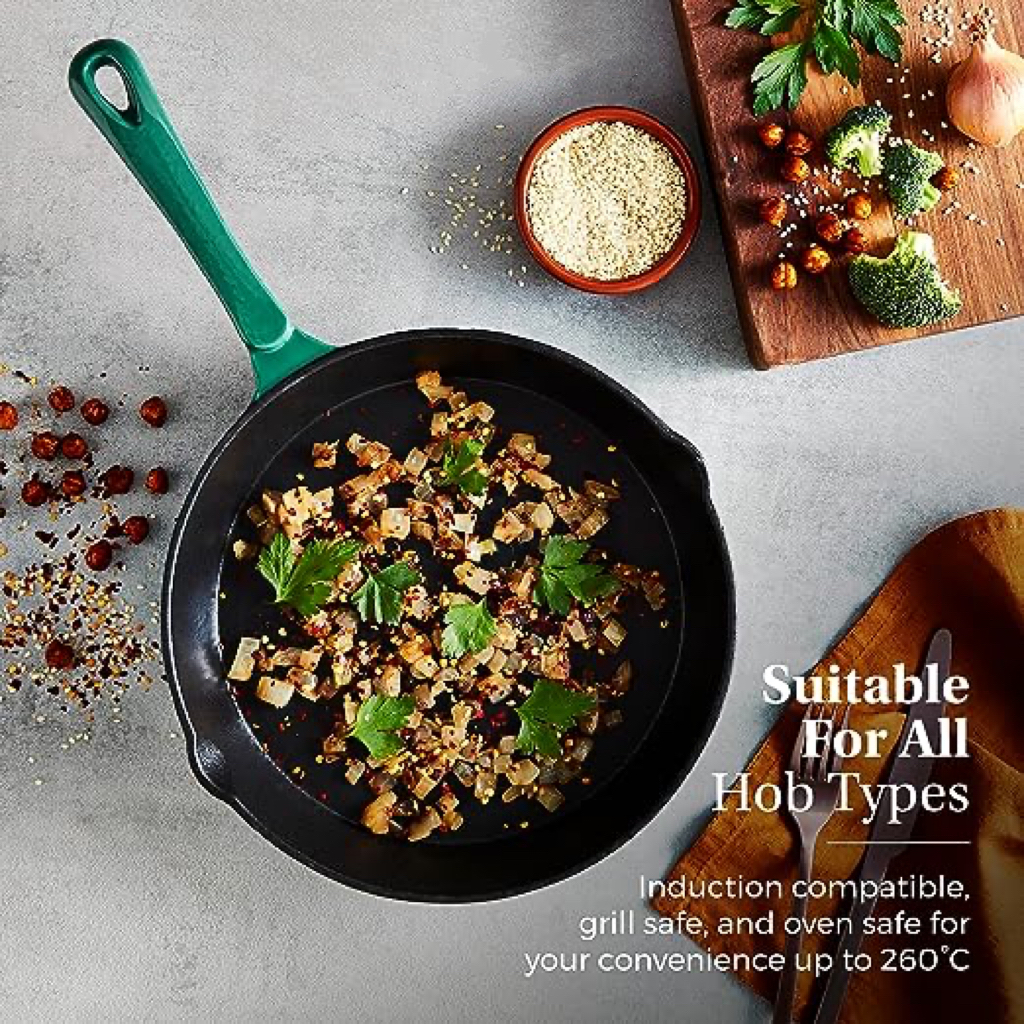

It can be used for frying, sautéing, searing, baking, or even boiling water It can be used for frying, sautéing, searing, baking, or even boiling water

It can be used for frying, sautéing, searing, baking, or even boiling water It can be used for frying, sautéing, searing, baking, or even boiling water Regular seasoning with oil helps prevent rusting and creates a non-stick surface, eliminating the need for excessive oil or butter during cooking Regular seasoning with oil helps prevent rusting and creates a non-stick surface, eliminating the need for excessive oil or butter during cooking

Regular seasoning with oil helps prevent rusting and creates a non-stick surface, eliminating the need for excessive oil or butter during cooking Regular seasoning with oil helps prevent rusting and creates a non-stick surface, eliminating the need for excessive oil or butter during cooking

It's equally at home in the oven, on a campfire, or even a grill, making it a truly versatile addition to any kitchen It's equally at home in the oven, on a campfire, or even a grill, making it a truly versatile addition to any kitchen

It's equally at home in the oven, on a campfire, or even a grill, making it a truly versatile addition to any kitchen It's equally at home in the oven, on a campfire, or even a grill, making it a truly versatile addition to any kitchen

Comment area