- Top: 5625Step on: 911

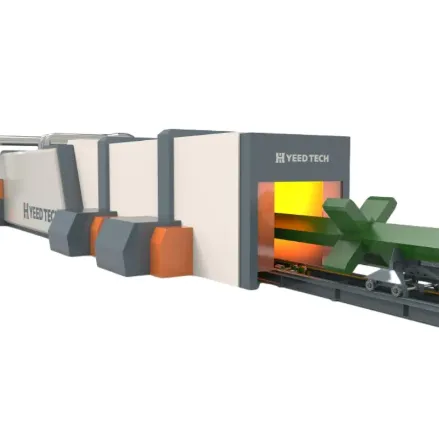

tagakolekta ng alikabok at usok

People involved | Date:2025-08-16 09:58:15

Related articles

Sustainability and Cost Savings with Automatic Paint Spraying Equipment Projects

Lastly, the size and portability of the unit should align with the workspace layout. A compact design may be ideal for smaller areas, while larger models might be suitable for bigger factories or workshops.

This struggle is universal. Most people, regardless of their background, can relate to the feeling of carrying burdens—be it the pressure of societal expectations, the desire for personal achievement, or the quest for stability in uncertain times. At times, the sheer weight of these burdens can feel overwhelming, much like a heavy container threatening to tip over. However, just like the individuals seen in our communities, we too can find ways to balance and manage these weights.

The Role of Forklifts in Container Handling and Delivery

Generally made of high-strength steel, stacking bars are designed to withstand significant pressure and impact. They are typically mounted on the top corners of a container and fit into designated notches on the bottom of the container stacked above it. This design allows for a seamless interlocking mechanism that provides additional stability to the stacked containers.

For those considering the transition to automated systems, understanding the initial investment versus long-term gains is essential. While the upfront cost may appear daunting, the return on investment is realized through improved throughput, lower labor costs, and reduced material waste. Consulting with experienced professionals during the planning and implementation phase is crucial, as they can provide insights tailored to specific industry needs and operational scales.

4. Cost-Effective Solutions Investing in portable ventilation can be more economical in the long run. By reducing health risks and improving worker productivity, companies can save on healthcare costs and enhance overall operational efficiency.

In conclusion, exhaust ventilation plays a vital role in maintaining a safe and healthy welding environment. As the welding industry continues to grow, the need for effective ventilation systems becomes increasingly apparent. By adopting appropriate ventilation strategies and adhering to best practices, industries can protect their workers from the harmful effects of welding fumes. Ultimately, ensuring the health and safety of workers not only enhances productivity but also contributes to a more sustainable and responsible workplace.

When selecting a welding fume extractor, several factors should be considered

Comment area