- Top: 8Step on: 6

Shijiazhuang TangChao Metal 5 tomato cages

People involved | Date:2025-08-15 02:22:55

Related articles

The ongoing investments in infrastructure and technology by global trade networks indicate a bright future for container handlers. These machines will remain key elements in achieving the efficiency and speed required to succeed in a competitive and ever-changing marketplace.

In addition to improving efficiency and precision, automatic spray painting systems contribute to sustainability efforts by reducing waste and energy consumption. Traditional methods often lead to overspray and wasted materials, but these automated systems are designed to optimize every aspect of the painting process.

The Importance of Welding Fume Management

- Mobile or Portable Units These are versatile systems that can be moved around the worksite, making them ideal for projects that involve welding in various locations. They feature built-in fans and filtration systems.

In conclusion, automated spray coating systems represent a fusion of innovation, expertise, and reliability. By embracing these cutting-edge technologies, manufacturers can achieve unparalleled precision and efficiency, positioning themselves as leaders in their respective industries. As these systems continue to evolve, their role in advancing manufacturing processes will only become more pronounced, offering endless possibilities for the future of industrial production.

In the world of modern manufacturing, precision and adaptability are key to achieving high-quality results. The advent of automatic paint spray machines has revolutionized how industries handle diverse coating applications. These machines are not only efficient but also versatile, offering tailored solutions for various industrial needs. From the intricacies of small-scale projects to large-scale production, automatic paint sprayer machines deliver consistent performance.

The integration of automatic spray painting machines into manufacturing processes represents a significant step toward the future of industrial production. These machines combine speed, precision, and quality, making them a valuable investment for businesses seeking to optimize their operations.

In the logistics and shipping industries, efficient container handling is crucial to ensure safe and timely delivery of goods. One of the essential aspects of container handling is understanding the elevation marking system, commonly known as the marco de elevación del contenedor ISO. This system provides valuable information regarding the structural integrity and handling capabilities of ISO containers, which are standardized intermodal freight containers used worldwide.

Furthermore, the integration of digital technology in automatic paint dispensers means they can easily be updated with software enhancements, ensuring they remain at the cutting edge of paint technology. Users can benefit from the latest advances without the need to purchase entirely new machines, illustrating the long-term value and sustainability of investing in such a device.

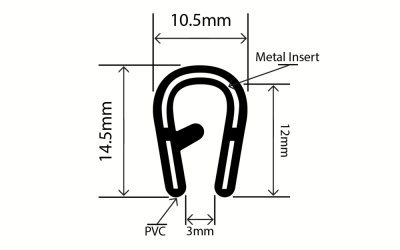

The stripping is then carefully applied along the intended areas, with special attention paid to corners and seams to prevent any leaks The stripping is then carefully applied along the intended areas, with special attention paid to corners and seams to prevent any leaks

The stripping is then carefully applied along the intended areas, with special attention paid to corners and seams to prevent any leaks The stripping is then carefully applied along the intended areas, with special attention paid to corners and seams to prevent any leaks

Comment area