- Top: 5179Step on: 77

wall tie survey

People involved | Date:2025-08-16 07:03:35

Related articles

For companies considering the shift towards automated systems, the selection process can be daunting. Factors such as the specific requirements of the coating process, the compatibility of materials, and the scale of production must be carefully weighed. Collaborating with suppliers who have a proven track record and offer tailored solutions is crucial in ensuring successful integration and operation.

The welding process releases fumes containing various harmful substances, including metallic oxides, silicates, and gases like ozone and nitrogen dioxide. Prolonged exposure to these fumes can pose serious health risks to welders, including respiratory issues, irritation of the eyes and throat, and long-term conditions such as lung cancer. Using an exhaust arm can significantly reduce these risks by ensuring that harmful fumes are promptly captured and removed from the work area.

3. Disposal or Recycling After filtration, the cleaned air is either returned to the workspace or expelled outside, depending on local regulations and safety protocols. Some advanced systems also allow for the recycling of collected materials, reducing waste and promoting sustainability.

Features to Consider

Selection Criteria for Portable Fume Extractors

The primary function of a forklift container is to optimize the use of forklifts in material handling. By utilizing containers, businesses can

- - Suction Power The effectiveness of an extractor often depends on its suction power. Select a unit that can handle the volume of fumes produced by the welding process being conducted.

The Impact on Construction Efficiency

Some advanced models even feature ergonomic handles and smooth-reeling mechanisms for added comfort and control Some advanced models even feature ergonomic handles and smooth-reeling mechanisms for added comfort and control

Some advanced models even feature ergonomic handles and smooth-reeling mechanisms for added comfort and control Some advanced models even feature ergonomic handles and smooth-reeling mechanisms for added comfort and control

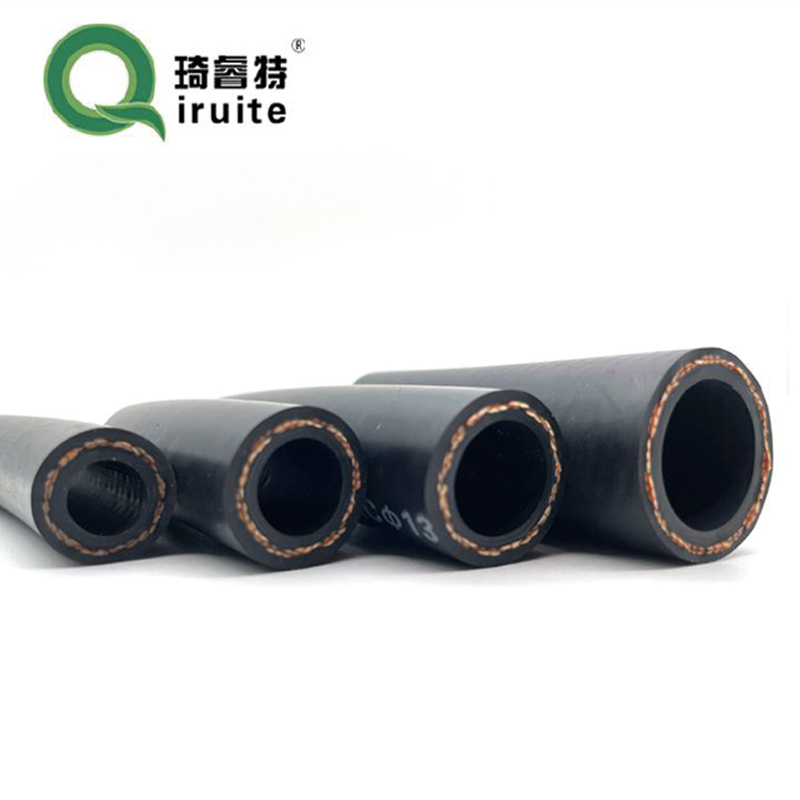

They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions

They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions

Comment area