- Top: 867Step on: 48717

floral design chicken wire

People involved | Date:2025-08-16 10:29:27

Related articles

This enhancement in efficiency leads to faster production cycles, allowing companies to meet increasing demands without compromising on quality. As consumers expect quick delivery times and higher standards, the need for speed in production has never been more critical. Automatic systems meet this demand by ensuring that every piece of equipment is working optimally to deliver results rapidly.

In summary, automatic spray coating machines represent a crucial investment for any industry focused on enhancing production quality and efficiency. By leveraging cutting-edge technology and comprehensive support, these machines offer unparalleled benefits that are recognized by experts and trusted by leading manufacturers worldwide. With their ability to deliver consistent and high-quality results, they are not just machines; they are the cornerstone of a modern, efficient, and competitive manufacturing operation.

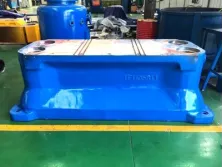

The integration of steel structure manufacturing equipment with automatic spray painting systems has transformed how manufacturers handle large-scale production. These machines provide consistent and even coatings, ensuring that every piece meets stringent quality standards.

Telescopic container handlers are specialized machines designed to lift, stack, and move shipping containers of varying sizes and weights. Unlike traditional forklifts, these handlers are equipped with a telescoping arm, enabling them to extend and retract as needed. This feature allows operators to reach containers located at significant heights and depths without needing auxiliary equipment or additional maneuvers. The design also includes a cab that provides excellent visibility, ensuring the safety and efficiency of operations.

Efficiency is a critical factor in modern production lines, and automatic paint spraying robots play a pivotal role in optimizing operations. These robots can operate continuously, significantly reducing downtime and boosting productivity.

The Welding Fume Extraction System A Key Component in Workplace Safety

6. Cost-Effectiveness Although the initial investment in robotic technology can be high, the long-term savings achieved through increased efficiency, reduced waste, and minimized labor costs significantly outweigh the upfront costs. Companies that adopt this technology often see a quick return on investment.

A typical WFES consists of several components designed to efficiently capture fumes and dust. The main elements of such a system include

Comment area