- Top: 35513Step on: 1829

Shijiazhuang TangChao Metal 7 ft welded wire fencing

People involved | Date:2025-08-16 07:33:37

Related articles

Welding extraction systems ensure that toxic gases and particles are safely removed from the work environment, preventing respiratory issues among workers. These systems work seamlessly alongside the automated welding arms to create an environment where the focus can remain solely on achieving precise welds, without worrying about exposure to harmful fumes.

In the realm of contemporary architecture and construction, insulated metal panel (IMP) buildings have emerged as a highly effective solution for a variety of applications. These structures, known for their energy efficiency, durability, and aesthetic appeal, are quickly becoming the preferred choice for many industries, including commercial, industrial, and even residential projects.

2. Sustainability Focus With growing awareness of environmental issues, automatic ink dispensers will likely incorporate greener technologies. Innovations may include the use of eco-friendly inks and more energy-efficient designs to appeal to environmentally conscious consumers and businesses.

4. Noise Levels Consider the noise produced by the extractor, as excessive noise can be distracting and contribute to a stressful working environment.

La Revolución del Spray Automatización y Sprayfärg

Saldırış Gazlarini Yo'qotish Tizimlariga Umumiy Nazariyaya

Initially, automated paint spraying systems were limited and often involved expensive and bulky machinery. However, advancements in robotics, nanotechnology, and artificial intelligence have given rise to more compact, sophisticated robots capable of performing intricate tasks. With rapid technological advancements, today's paint spraying robots are more accessible and versatile than ever before.

Steel floor systems are now integral to various types of construction projects. They are commonly employed in the following applications

The automated painting process revolutionizes production lines by reducing downtime and increasing throughput. By automating repetitive tasks, manufacturers can allocate resources more effectively and focus on innovation.

With a commitment to quality and innovation, Yeed Tech Co., Ltd. stands out as a premier manufacturer of welding fume extractors. Their products are engineered to meet the diverse needs of the welding industry while ensuring worker safety and compliance with health regulations. From small units for hobbyists to mobile solutions for on-site work and specialized equipment for laser applications, Yeed Tech Co., Ltd. has the right fume extractor to suit your specific needs. By choosing Yeed Tech Co., Ltd., you are investing in quality, efficiency, and a healthier future for your welding projects.

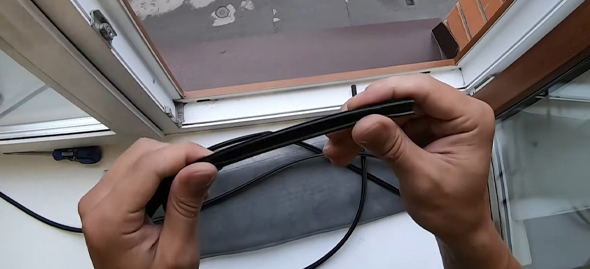

It's essential to choose weather stripping that is durable and can withstand the fluctuations in temperature and humidity It's essential to choose weather stripping that is durable and can withstand the fluctuations in temperature and humidity

It's essential to choose weather stripping that is durable and can withstand the fluctuations in temperature and humidity It's essential to choose weather stripping that is durable and can withstand the fluctuations in temperature and humidity

Comment area