- Top: 2124Step on: 6

Shijiazhuang TangChao Metal rebar positioner

People involved | Date:2025-08-14 06:20:52

Related articles

Understanding the various types of container handling equipment is crucial for optimizing your operations. At Yeed Tech Co., Ltd., we provide an extensive selection of equipment tailored to meet diverse handling needs. Our range includes:

In conclusion, the proposed automatic paint spraying equipment presents a revolutionary advancement in industrial painting processes. By enhancing efficiency, improving quality, and reducing costs, this project aligns with the goals of modern industries seeking to optimize operations. Through careful planning and execution, the implementation of this system promises to deliver substantial value and set new benchmarks in the field of automated painting.

Each portable fume extractor is crafted with high-quality materials and cutting-edge filtration systems. We also offer excellent customer support to help you select the right equipment for your needs, ensuring a seamless experience from purchase to operation.

4. Long-term Health Benefits Investing in air extractors is not just about immediate benefits; it is also a proactive approach to long-term health. By minimizing exposure to harmful substances, companies can help prevent chronic health issues among their workforce, leading to fewer sick days and lower healthcare costs.

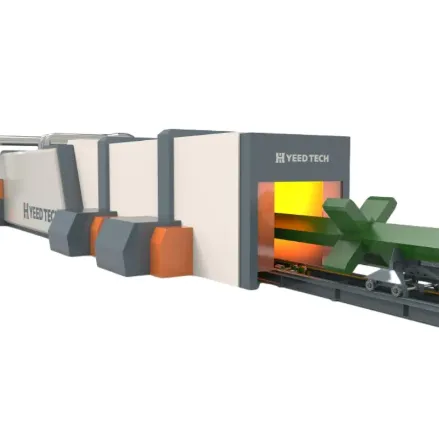

The proposed automatic paint spraying equipment will integrate advanced robotics and precision engineering technologies. The key components of the system will include

- 2. Weight Capacity The markings often include information about the maximum load capacity of the container. This helps operators understand how much weight can be safely lifted and transported, reducing the risk of accidents during handling.

2. Speed of Construction Steel components are often prefabricated, allowing for faster assembly on-site. The use of steel systems can significantly reduce construction time, enabling projects to be completed ahead of schedule, which is particularly advantageous in commercial and industrial applications.

There are several types of ventilation systems that can be employed in robotic welding environments

. Each system has its advantages and is suited to different application needs.Integration of such systems requires a strategic approach

. It involves a thorough analysis of existing production lines, a clear understanding of desired outcomes, and careful planning to minimize disruption. Companies that have successfully transitioned to automated spray coating systems often report significant improvements in quality assurance processes, facilitating smoother operations and enhancing customer satisfaction.

Comment area