- Top: 6254Step on: 55273

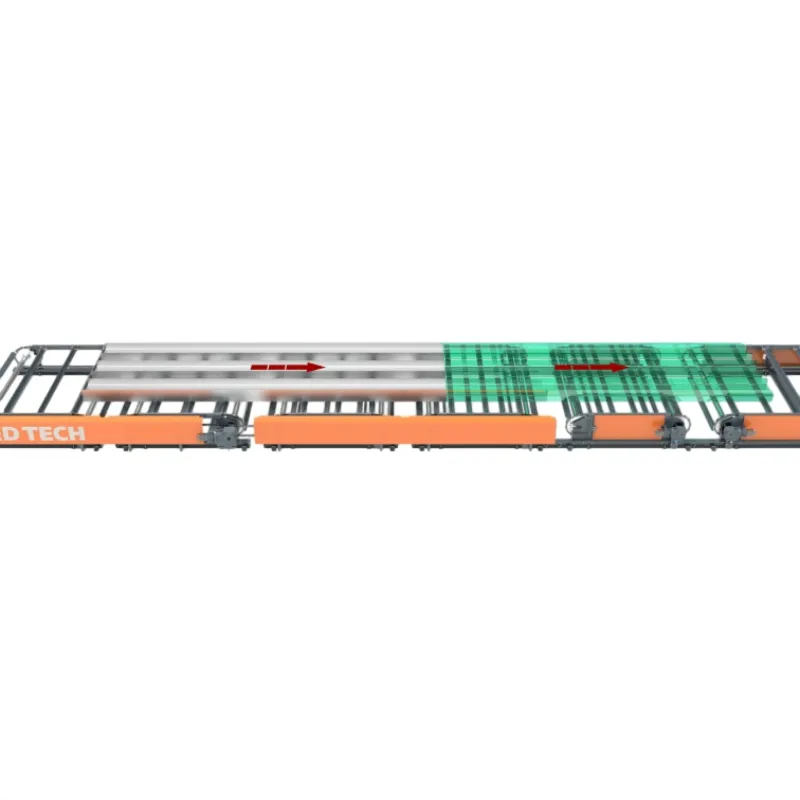

pengekstrakan teluk kimpalan

People involved | Date:2025-08-14 07:01:45

Related articles

Understanding the ISO Container Elevation Marking System

3. Technical Support and Training Implementing new spray coating equipment often requires training. A good manufacturer will provide comprehensive training programs and technical support to help clients maximize their investment and ensure proper operation.

Whether it's capturing the particulate matter generated by the welding process or filtering out harmful gases, these units play a critical role in maintaining air quality. The industrial fume extractors within these units are designed to handle the high volume of fumes generated in industrial settings, ensuring that air quality stays within safe limits even during high-intensity operations.

1. Regular Maintenance Ensure that fume extraction systems are regularly inspected and maintained to operate at peak efficiency. This includes cleaning filters, checking for blockages, and ensuring that fans and motors are functioning correctly.

Investing in portable ventilation systems for welding is not just a matter of compliance with safety regulations; it's essential for promoting a healthy workplace. With a variety of options available, businesses can choose the right systems tailored to their specific needs. By ensuring that welders have access to safe, breathable air, companies not only protect their workforce but also enhance productivity and create a positive working environment. In the long run, the benefits of portable ventilation systems far outweigh the costs, making them a smart investment for any welding operation.

Conclusion

4. Reduced Material Waste By providing accurate cuts, H-beam cutting machines help minimize material waste. This efficiency not only saves costs but also supports sustainable practices in the industry by reducing excess scrap.

Another crucial benefit of automatic spray painting is the consistency it brings to the finishing process. Manual painting can vary greatly depending on the skill level of the worker, environmental conditions, and even fatigue. Automatic systems eliminate these variables by using precise robotics and programmed controls to ensure that every coat is applied evenly across all surfaces.

- 2. Weight Capacity The markings often include information about the maximum load capacity of the container. This helps operators understand how much weight can be safely lifted and transported, reducing the risk of accidents during handling.

Comment area