- Top: 64Step on: 71

Shijiazhuang TangChao Metal metal wire grid wall panel

People involved | Date:2025-08-16 10:52:59

Related articles

Discover the Future of Shipping Container Lifting Equipment

Choosing the Right System

- Manufacturing In factories, the Górny Podnośnik is employed for assembly lines where heavy components must be lifted and placed accurately, streamlining the manufacturing process.

At the heart of these machines is their ability to offer a consistent and high-quality finish, a key differentiator from manual painting techniques. The integration of advanced robotics and control systems ensures that paint is applied uniformly, reducing the incidence of human error and enhancing the overall aesthetic appeal of the product. With automatic spray painting machines, manufacturers can achieve a flawless finish that meets stringent industry standards and consumer expectations.

Why Choose Yeed Tech Co., Ltd. for Your Fume Extraction Needs?

As technology continues to evolve, the future of container transportation control equipment is poised for significant advancements. The integration of artificial intelligence and machine learning holds the potential to revolutionize how logistics operate. For instance, predictive analytics can help companies anticipate delays, optimize routes, and manage inventory more effectively.

Power meets convenience with the hydraulic shipping container lift from Yeed Tech Co., Ltd. This cutting-edge equipment is perfect for businesses that require heavy-duty lifting capabilities and versatility. Utilizing advanced hydraulic systems, our shipping container lift can handle even the heaviest containers with ease, reducing manual labor and increasing safety for your team.

Air extractors are designed to remove contaminated air from the welding area, ensuring that workers are not exposed to harmful fumes. They work by capturing pollutants directly at the source, often using localized exhaust systems like fume hoods or capture arms that are positioned near the welding site. The collected air is then filtered and either cleaned or expelled outside, significantly reducing the concentration of toxins in the air that workers breathe.

3. Technical Support and Training Implementing new spray coating equipment often requires training. A good manufacturer will provide comprehensive training programs and technical support to help clients maximize their investment and ensure proper operation.

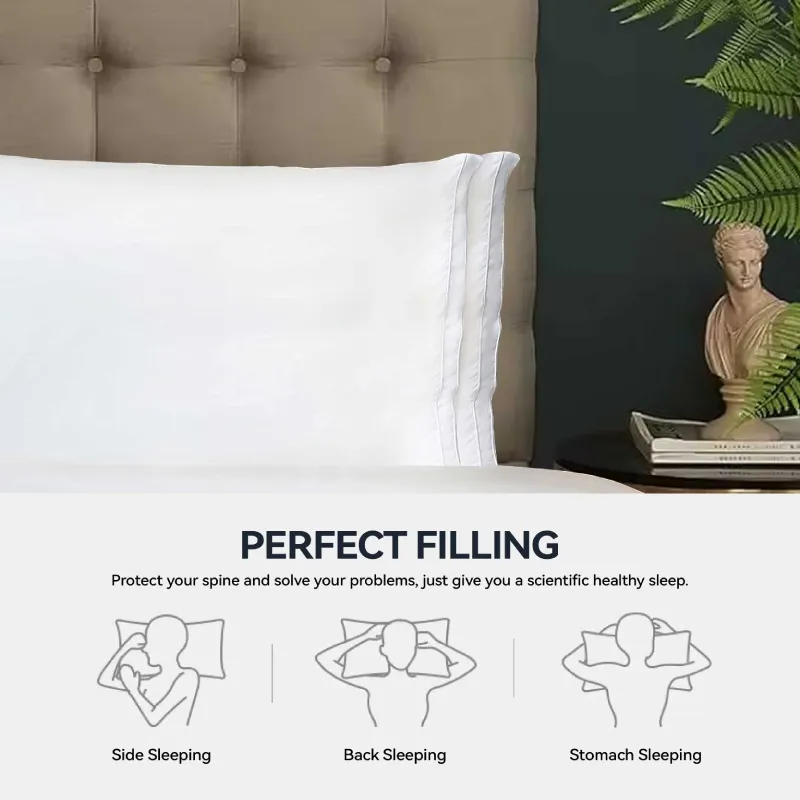

They symbolize the transition from the outside world into a private sanctuary They symbolize the transition from the outside world into a private sanctuary

They symbolize the transition from the outside world into a private sanctuary They symbolize the transition from the outside world into a private sanctuary Here are some tips to help you make an informed decision

Here are some tips to help you make an informed decision

This means that you can enjoy your new sheets for years to come without having to replace them as frequently This means that you can enjoy your new sheets for years to come without having to replace them as frequently

This means that you can enjoy your new sheets for years to come without having to replace them as frequently This means that you can enjoy your new sheets for years to come without having to replace them as frequently The familiar feel of home, even in a clinical setting, can help patients relax and promote healing The familiar feel of home, even in a clinical setting, can help patients relax and promote healing

The familiar feel of home, even in a clinical setting, can help patients relax and promote healing The familiar feel of home, even in a clinical setting, can help patients relax and promote healing

Comment area