- Top: 7377Step on: 654

pengudaraan ekzos kimpalan

People involved | Date:2025-08-14 17:22:12

Related articles

Ultimately, the Last Container Lyft embodies a forward-thinking approach to logistics that balances efficiency, cost-effectiveness, and sustainability. As more companies recognize the importance of eco-friendly practices and the need for seamless delivery systems, the Last Container Lyft could emerge as a standard in the industry. Its potential to transform the logistics landscape while addressing pressing environmental concerns presents an exciting opportunity for the future of transportation.

Features to Consider

Invest in your wellbeing and the health of your team with our reliable welding fume extraction solutions. Together, we can ensure a safer future for your welding operations!

Ultimately, the Last Container Lyft embodies a forward-thinking approach to logistics that balances efficiency, cost-effectiveness, and sustainability. As more companies recognize the importance of eco-friendly practices and the need for seamless delivery systems, the Last Container Lyft could emerge as a standard in the industry. Its potential to transform the logistics landscape while addressing pressing environmental concerns presents an exciting opportunity for the future of transportation.

- - Electrostatic Spray This technique uses electrical charges to attract paint particles to the surface being coated, resulting in a more uniform application with minimal overspray.

When searching for a spray coating equipment manufacturer, several key factors should be taken into account

As industries continue to evolve, the need for advanced steel structure painting solutions becomes increasingly evident. Automatic spray painting machines address these demands by offering unparalleled precision, efficiency, and adaptability.

1. Increase Efficiency Forklift containers enable quick loading and unloading processes, which directly reduces labor time and increases throughput.

4. Specialty Rods Specialty rods, including those for aluminum or high-temperature applications, cater to specific needs. Aluminum rods are designed for welding aluminum and its alloys, and high-temperature rods are used in situations that require heat resistance.

When used in conjunction with automated welding arms, a portable fume extraction system ensures that fumes do not linger and interfere with the process. As the welding arm continues its work, the fume extractor removes contaminants, enabling uninterrupted and productive operations. This seamless integration allows companies to maintain both productivity and a safe working environment.

The right packaging can protect the product from damage during shipping and storage, while also appealing to your target audience The right packaging can protect the product from damage during shipping and storage, while also appealing to your target audience

The right packaging can protect the product from damage during shipping and storage, while also appealing to your target audience The right packaging can protect the product from damage during shipping and storage, while also appealing to your target audience It fosters economic growth in producing regions by providing income opportunities and promoting rural development It fosters economic growth in producing regions by providing income opportunities and promoting rural development

It fosters economic growth in producing regions by providing income opportunities and promoting rural development It fosters economic growth in producing regions by providing income opportunities and promoting rural development

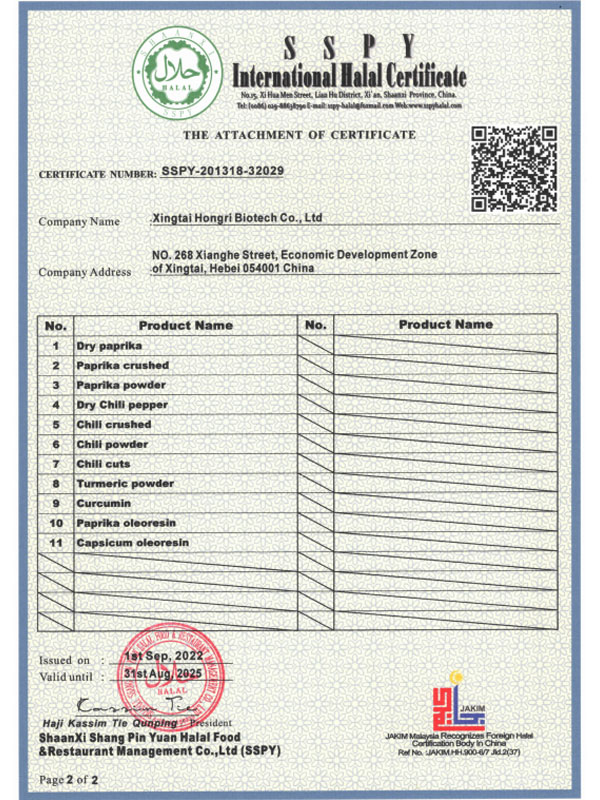

Their compliance with stringent foreign standards has opened doors to lucrative markets in Europe, North America, and Asia Their compliance with stringent foreign standards has opened doors to lucrative markets in Europe, North America, and Asia

Their compliance with stringent foreign standards has opened doors to lucrative markets in Europe, North America, and Asia Their compliance with stringent foreign standards has opened doors to lucrative markets in Europe, North America, and Asia

Comment area