- Top: 772Step on: 436

fully compressed spring

People involved | Date:2025-08-14 15:07:34

Related articles

The Górny Podnośnik exemplifies the intersection of innovation and practicality in the lifting industry. With its robust features, emphasis on safety, and wide-ranging applications, it is no wonder that this upper lift system is becoming increasingly popular in various sectors. As industries continue to evolve, technologies like the Górny Podnośnik will remain at the forefront, enhancing productivity and ensuring a safer working environment for all. With a focus on efficiency, safety, and ergonomic design, the future looks bright for lifting technologies like the Górny Podnośnik, paving the way for more advanced solutions in the years to come.

Several types of spray coating methods are commonly used

Expertise in developing these systems stems from a deep understanding of fluid dynamics, mechanical engineering, and software integration. Manufacturers of automated spray coating systems employ highly specialized engineers who design and optimize every component to ensure maximum performance and longevity. They take into account factors such as viscosity, surface tension, and evaporation rates of coating materials, tailoring each system to meet specific industry requirements.

1. Lifting Points The locations where cranes and other lifting equipment should attach to the container for safe lifting. Ensuring the correct attachment points helps prevent damage to the container and the cargo it holds.

Elevate Your Project with the Automatic Spray Painting Machine Project

- Time Savings Automated systems can operate continuously without breaks, significantly speeding up production times.

Conclusion

Enhancing Efficiency with Automatic Paint Spraying Robots

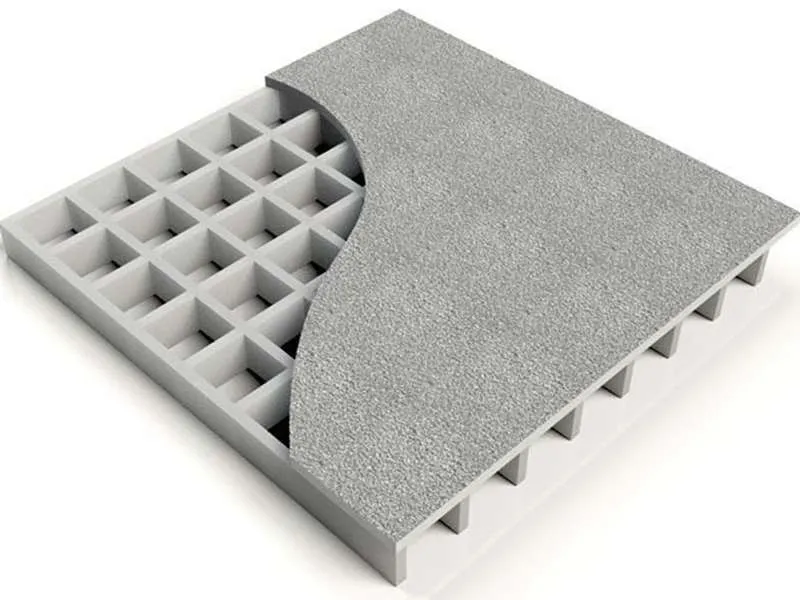

The insulation reduces the need for additional heating or cooling systems, thus saving energy and reducing operational costs The insulation reduces the need for additional heating or cooling systems, thus saving energy and reducing operational costs

The insulation reduces the need for additional heating or cooling systems, thus saving energy and reducing operational costs The insulation reduces the need for additional heating or cooling systems, thus saving energy and reducing operational costs

Comment area