- Top: 789Step on: 43

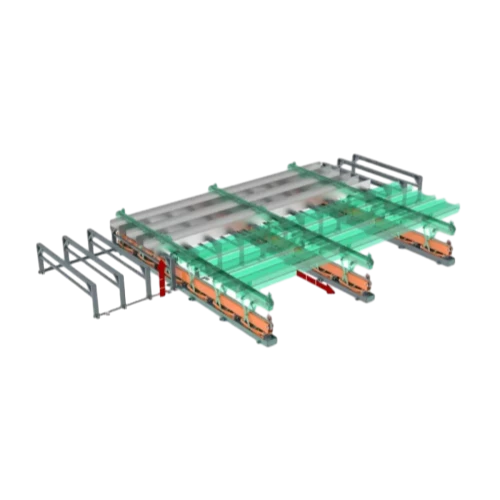

Shijiazhuang TangChao Metal hy rib construction joint

People involved | Date:2025-08-14 06:29:03

Related articles

The Role of H-Beam Cutting Machines

These systems can handle a variety of coatings, from anti-corrosion layers to decorative finishes, making them versatile tools for industries ranging from construction to automotive manufacturing. With features like real-time monitoring and programmable settings, businesses can ensure that every project meets the highest standards of quality.

By incorporating steel structure processing equipment into the painting line, manufacturers can address the specific needs of large-scale projects. This integration enhances the durability of coatings, protects materials from corrosion, and ensures a flawless appearance.

- 4. Deployment Once the system meets all standards, we will proceed with installing the equipment in the designated production areas.

Experience with automatic spray coating machines suggests that their greatest advantage lies in their ability to provide consistent and uniform coating application. This consistency is crucial as it directly impacts the aesthetic appeal and durability of the final product. For industries like automotive, where surface perfection is non-negotiable, these machines are indispensable. An operator with experience in manual spraying methods will immediately notice the stark improvement in both speed and quality when transitioning to automated systems.

Understanding the various types of container handling equipment is crucial for optimizing your operations. At Yeed Tech Co., Ltd., we provide an extensive selection of equipment tailored to meet diverse handling needs. Our range includes:

1. Type of Welding Different welding processes produce varying amounts and types of fumes. For instance, MIG and TIG welding generate different fume profiles than stick welding.

The rise of automatic paint spraying robots has marked a significant milestone in industrial painting processes. Their precision, efficiency, and ability to streamline operations while ensuring safety make them a valuable asset for manufacturers. As technology continues to advance, we can expect further enhancements in these systems, leading to even more innovative solutions in the realm of industrial painting. As industries adopt these robots, the future of manufacturing looks brighter and more efficient than ever before.

Furthermore, companies investing in automated spray coating systems routinely conduct comprehensive training programs to ensure that their workforce understands and leverages the full potential of these technologies. By maintaining transparency with clients and continuously updating system capabilities, manufacturers reinforce their commitment to quality and innovation.

Comment area