- Top: 264Step on: 569

Shijiazhuang TangChao Metal welded wire mesh manufacturers

People involved | Date:2025-08-14 16:00:07

Related articles

Understanding the various types of container handling equipment is crucial for optimizing your operations. At Yeed Tech Co., Ltd., we provide an extensive selection of equipment tailored to meet diverse handling needs. Our range includes:

From a practical perspective, adopting automatic spray painting machines significantly enhances production throughput. The machines can operate continuously with minimal downtime for maintenance, unlike manual labor which is subject to fatigue and inconsistency. This scalability allows businesses to meet rising demands without compromising on quality or delivery timelines.

When selecting a forklift container, several design factors should be taken into account

3. Top Loaders As their name suggests, these machines lift containers from the top and are often used for stacking. They have a lower lifting capacity than other handlers but are useful for specific applications where bottom access is restricted.

Installation of wall-mounted exhaust fans is typically straightforward, requiring minimal modifications to existing structures. Most models come with detailed instructions, making it accessible for DIY enthusiasts. Alternatively, professional installation services are readily available for those who prefer to leave it to the experts. Regardless of the approach, the result is a significant enhancement to indoor air quality and overall comfort.

Hơn nữa, hệ thống sơn tự động cũng thân thiện với môi trường hơn so với phương pháp sơn truyền thống. Bằng cách tối ưu hóa quy trình và sử dụng các công nghệ tiên tiến, lượng chất thải và ô nhiễm được giảm thiểu đáng kể. Điều này không chỉ giúp các doanh nghiệp tuân thủ các quy định về bảo vệ môi trường mà còn nâng cao hình ảnh thương hiệu trong mắt người tiêu dùng.

Steel floor systems are now integral to various types of construction projects. They are commonly employed in the following applications

The integration of portable welding fume extractors into welding operations is a step towards creating a safer and healthier work environment. As industries continue to prioritize worker safety and regulatory compliance, the adoption of these systems will likely become increasingly essential. By investing in quality portable fume extractors, businesses not only protect their employees but also foster a culture of safety and responsibility that benefits both the workforce and the company as a whole.

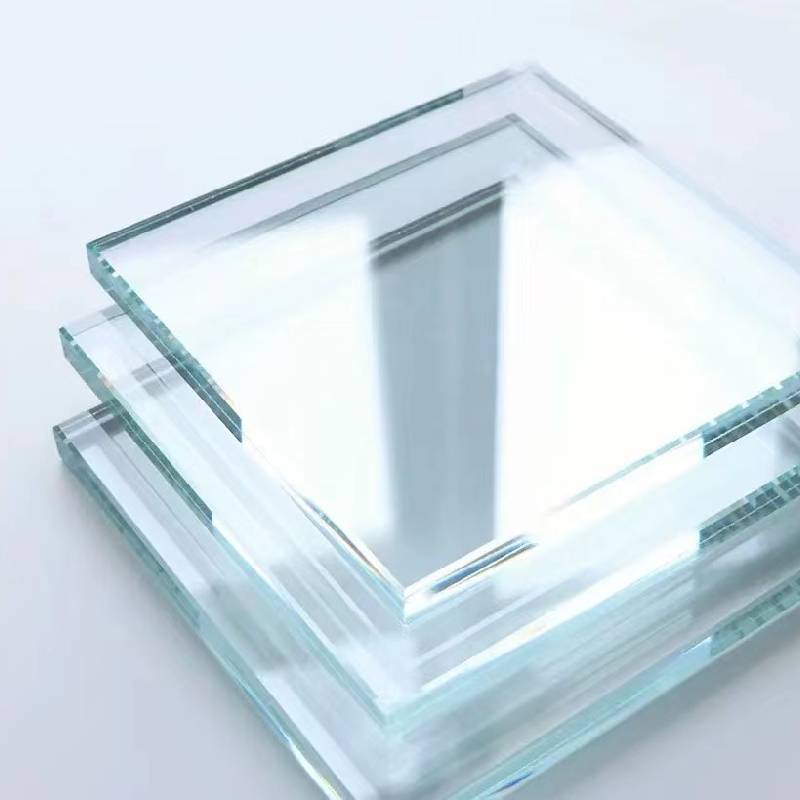

It consists of two or more layers of glass bonded together with a plastic interlayer It consists of two or more layers of glass bonded together with a plastic interlayer

It consists of two or more layers of glass bonded together with a plastic interlayer It consists of two or more layers of glass bonded together with a plastic interlayer

Comment area