- Top: 6Step on: 53

Shijiazhuang TangChao Metal 9 gauge field fence

People involved | Date:2025-08-14 16:52:50

Related articles

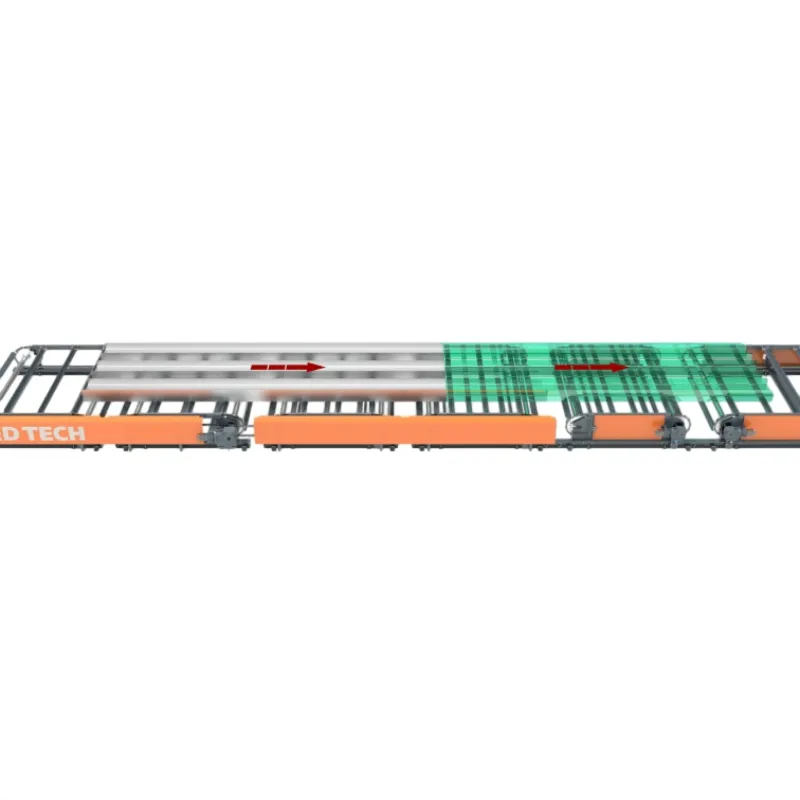

Automatic spray painting systems with conveyors further enhance safety by creating a physical separation between workers and hazardous operations. With automated equipment handling the painting process, employees can focus on other tasks in a safer environment. This shift not only reduces health risks but also boosts overall morale and job satisfaction.

2. Improved Air Quality By removing harmful particles from the air, a WFES dramatically improves indoor air quality. This not only protects welders but also benefits all employees working in proximity to welding operations.

However, while automation increases efficiency, it also requires a clean, safe environment to maintain optimal performance. This is where a portable welding ventilation system comes into play. Ensuring proper air quality can improve not just the effectiveness of the welding arms, but also worker health and the longevity of the machinery itself.

Applications of Steel Floor Systems

The Importance of Choosing the Right Spray Coating Equipment Manufacturer

Steel floor systems are now integral to various types of construction projects. They are commonly employed in the following applications

The Importance of Container Transportation Control Equipment

Applications of Steel Floor Systems

- الأحداث والنشاطات في الفعاليات العامة أو الحفلات، يمكن استخدام هذا النظام لضمان ألا يؤثر التدخين على الحضور.

In conclusion, the automatic spray painting machine is more than just a tool—it's a testament to the technological advancements shaping modern manufacturing. By aligning practical experience with professional expertise, and addressing the aspects of authority and trust, industries can harness these machines to redefine quality standards and operational excellence. Embracing this technology signifies not just an upgrade but an informed commitment to innovation and sustainable excellence in production.

Comment area