- Top: 8Step on: 6224

cattle fence

People involved | Date:2025-08-14 15:22:55

Related articles

Technological advancements have significantly transformed container loading platforms over the years. Automation is at the forefront of this evolution. Automated stacking cranes, for instance, can load and unload containers without the need for human intervention. This not only reduces labor costs but also improves safety by minimizing human error – a leading cause of accidents in busy freight environments.

3. Training and Awareness Providing welders with training on the risks associated with weld smoke and the importance of safety measures can lead to better compliance with safety protocols. Workers should be educated on how to recognize symptoms of exposure and the steps they can take to protect themselves.

Several types of spray coating methods are commonly used

To ensure optimal performance, regular maintenance of the exhaust arm is crucial. This includes cleaning filters, inspecting duct connections, and checking for any damage or blockages. It is essential to replace filters according to the manufacturer's recommendations, as clogged filters can diminish airflow and reduce the system's efficiency.

Local Exhaust Ventilation for Welding: The Key to Cleaner and Safer Workspaces

3. Accessibility Containers should be designed with features that facilitate easy access, such as open tops or removable sides, making it easier for workers to load and unload materials quickly.

1. Custom Solutions Every industry has unique requirements, and an experienced manufacturer understands this. They offer customized equipment and solutions that fit particular applications, enhancing productivity and reducing waste.

Achieving a Clean and Safe Workspace with Welding Smoke Extractors

If you notice any of these symptoms, it's important to take your Mercedes-Benz to a qualified mechanic for inspection and repair If you notice any of these symptoms, it's important to take your Mercedes-Benz to a qualified mechanic for inspection and repair

If you notice any of these symptoms, it's important to take your Mercedes-Benz to a qualified mechanic for inspection and repair If you notice any of these symptoms, it's important to take your Mercedes-Benz to a qualified mechanic for inspection and repair

To get an accurate estimate of the cost of the repair, it's best to contact a local repair shop and provide them with your vehicle's make, model, and year To get an accurate estimate of the cost of the repair, it's best to contact a local repair shop and provide them with your vehicle's make, model, and year

To get an accurate estimate of the cost of the repair, it's best to contact a local repair shop and provide them with your vehicle's make, model, and year To get an accurate estimate of the cost of the repair, it's best to contact a local repair shop and provide them with your vehicle's make, model, and year

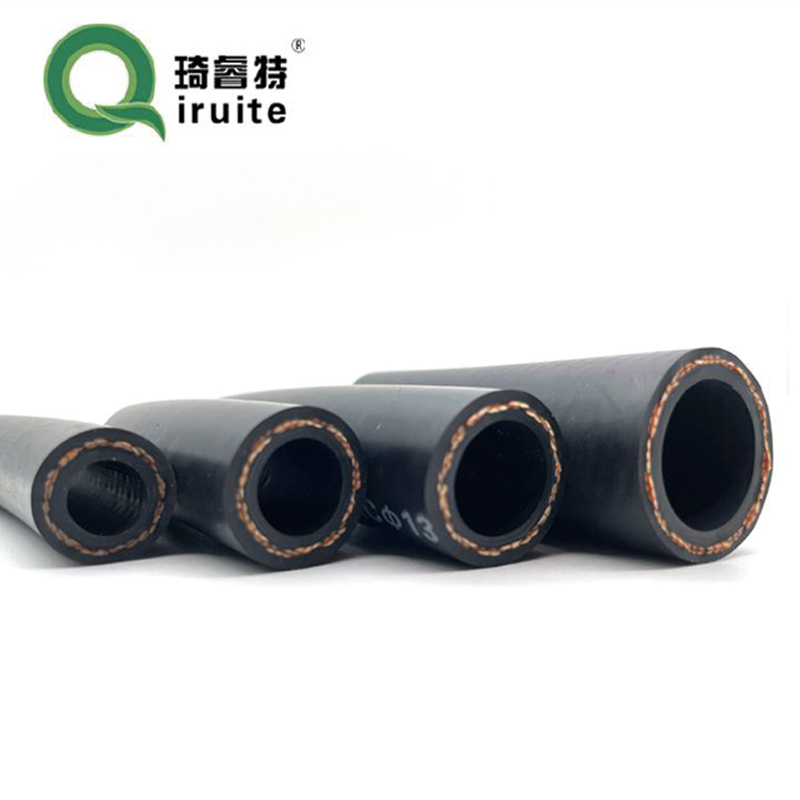

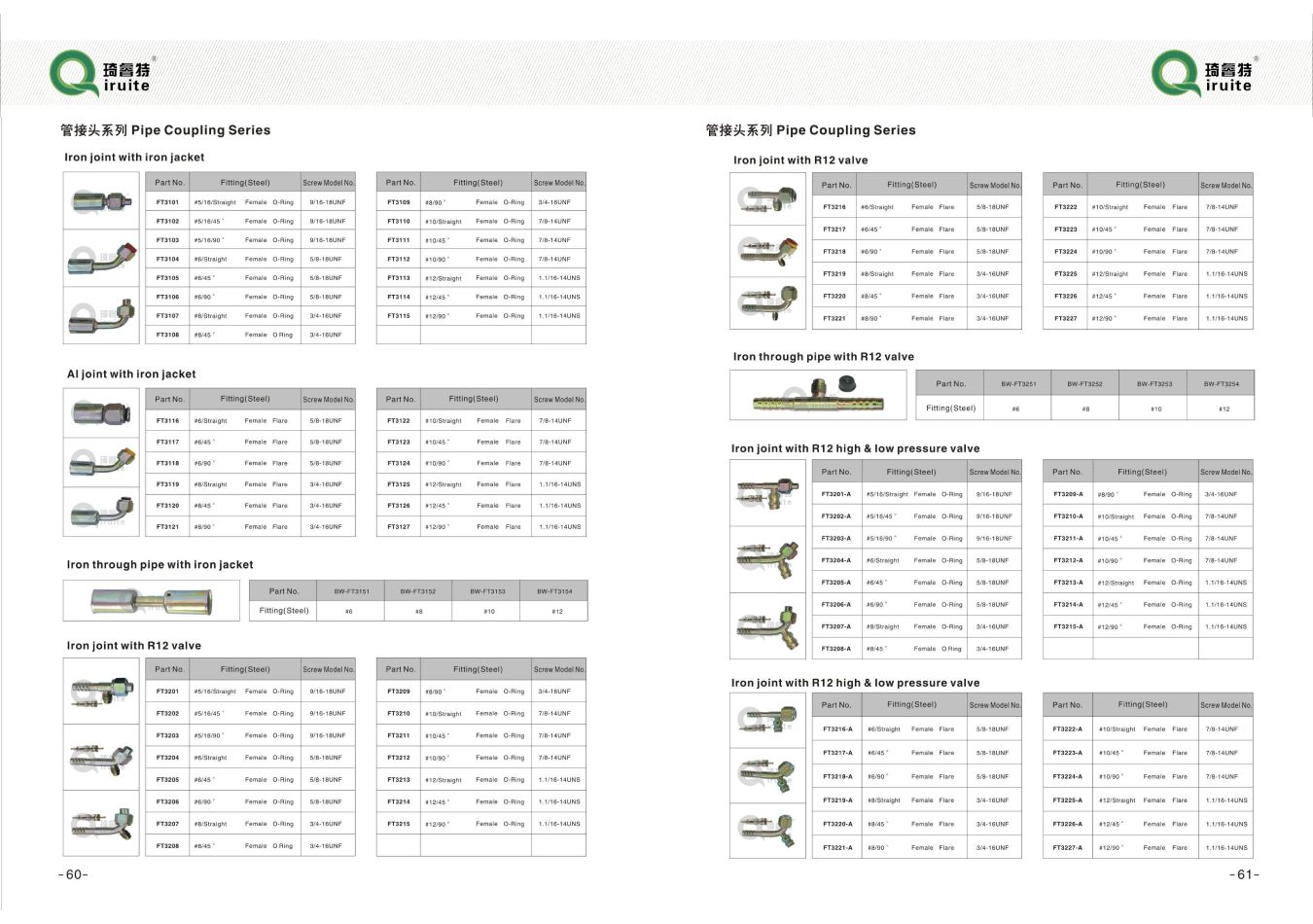

As the name suggests, this coupling requires soldering to create a secure bond between the pipe and the fitting As the name suggests, this coupling requires soldering to create a secure bond between the pipe and the fitting

As the name suggests, this coupling requires soldering to create a secure bond between the pipe and the fitting As the name suggests, this coupling requires soldering to create a secure bond between the pipe and the fitting

Regular inspections for signs of wear, damage, or leaks are essential Regular inspections for signs of wear, damage, or leaks are essential

Regular inspections for signs of wear, damage, or leaks are essential Regular inspections for signs of wear, damage, or leaks are essential They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions

They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions

Comment area