- Top: 53674Step on: 1197

welding dust collector

People involved | Date:2025-08-14 03:47:13

Related articles

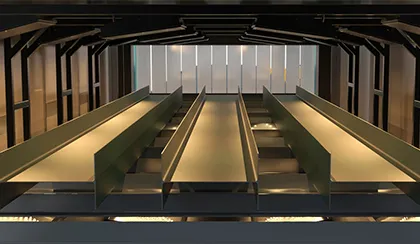

Automatic paint spraying equipment not only enhances the speed of operations but also ensures accuracy and resource optimization. These machines are equipped with advanced nozzles and adjustable settings, allowing manufacturers to customize the spray pattern, volume, and speed according to their specific needs.

Choosing the Right System

Unleash Efficiency with Automatic Paint Spraying Equipment

- Monitoring Air Quality Regular air quality monitoring can help identify pollution levels and assess the effectiveness of ventilation systems. This may involve using air sampling equipment to detect specific contaminants.

To summarize, the integration of automated spray coating systems into manufacturing processes represents a significant step forward for industries prioritizing quality, efficiency, and environmental responsibility. By embodying cutting-edge technology, these systems deliver a compelling return on investment, transforming the landscape of production operations. Manufacturers investing in these systems not only gain a competitive edge but also endorse a commitment to precision, cost savings, and eco-friendly practices. As the industry continues to advance, the adoption of automated solutions will undoubtedly play a pivotal role in shaping the future of manufacturing.

The Evolution and Importance of Container Loading Platforms

A crucial aspect of using automated welding arms is maintaining air quality within the workspace. The intense heat generated during welding creates smoke and fumes that can be harmful to workers and machinery alike. For this reason, portable fume extraction systems are invaluable. These systems are designed to quickly and efficiently remove harmful airborne particles from the environment, keeping the workspace safe and clean.

Tính Linh Hoạt và Ứng Dụng Đa Dạng

Comment area