- Top: 89Step on: 3

Hebei Chida cool roof relief

People involved | Date:2025-08-14 14:10:21

Related articles

Modern H-beam cutting machines incorporate advanced technology that enhances their performance. Here are some of the key features that make these machines indispensable

Бүгүнкү күндө рöкуппсалгачынын колдонуушунун саны өсууда, жана бул тенденциянын чыгарылышы айыл чарбасынын келечеги үчүн сонун перспективаларды сунуштайт. Технологиянын өнүгүүсү менен бирге, ал жаңы мүмкүнчүлүктөргө жана оптимизацияга жол ачат, мындайча айтканда – жумуш процессин жана айыл чарбасын жакшыртууга. Rökuppsamlare тютюн өндүрүшүн заманбап системага интеграциялайт жана экономиканы жогорулатуу жолунда жаңы кадамдарды сунуштайт.

The widespread adoption of automated spray painting machines is a testament to their transformative impact on industrial production. From enhancing efficiency and precision to supporting sustainability and worker safety, these systems address multiple challenges faced by modern manufacturers. With advancements such as automatic paint sprayers and automatic spray painting systems with conveyors, businesses can achieve consistent quality while optimizing costs and resources. As industries continue to prioritize innovation and sustainability, investing in automated paint spray systems is a forward-thinking decision that ensures long-term success.

Precision and Consistency with Automatic Paint Sprayer Machines

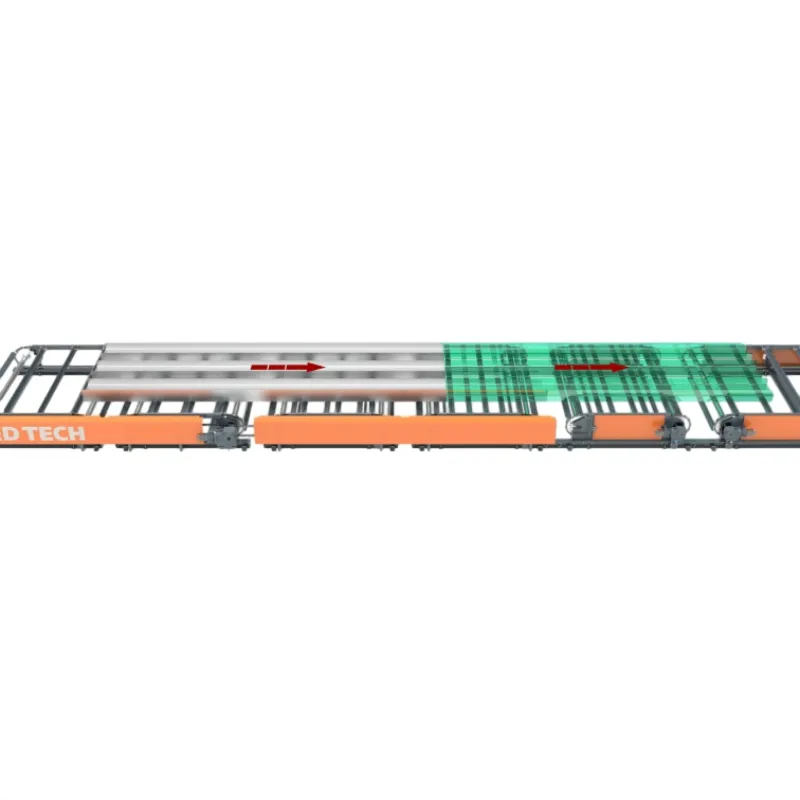

The integration of steel structure manufacturing equipment with automatic spray painting systems has transformed how manufacturers handle large-scale production. These machines provide consistent and even coatings, ensuring that every piece meets stringent quality standards.

The integration of an automatic spray painting system with conveyor further enhances this efficiency by automating the movement of items through the painting process. This eliminates bottlenecks and ensures a seamless workflow, making these systems ideal for high-volume production lines. Additionally, the precise application of paint minimizes material waste, leading to cost savings and a more sustainable operation.

By ensuring that the welding process is clean and efficient, manufacturers can improve productivity while meeting safety and environmental standards. With continued advancements in automation and air management, industries can achieve seamless joints in a more sustainable and efficient manner than ever before.

A clean and safe workspace is essential for maximizing productivity, and portable welding ventilation systems play a key role in this. These systems are especially valuable in dynamic and mobile operations, where flexibility and adaptability are crucial.

- Cost-Effectiveness While the initial investment in robotic welding technology may be significant, the long-term savings associated with reduced labor costs, less material wastage, and increased production efficiency often outweigh these expenses.

L'équipement pour le levage des conteneurs

Comment area