- Top: 48525Step on: 3

wholesale sign stakes

People involved | Date:2025-08-16 07:07:55

Related articles

5. User-Friendly Operations Many modern ink dispensers come equipped with intuitive interfaces and automation features, making them easy to use even for personnel without extensive technical training. This user-friendly design allows companies to integrate the technology seamlessly into their existing processes.

The use of high-quality fume extraction equipment means that the welding process can continue uninterrupted, without the need to pause for safety concerns or poor air quality. This contributes to the continuous and flawless operation of automated welding arms, reducing downtime and ensuring that every weld is perfect.

To complement the benefits provided by welding arms and mobile extraction units, fume ventilation systems are essential to any modern welding facility. These systems are designed to efficiently remove harmful airborne particles produced during welding, creating a safer and more comfortable environment for workers. By working alongside welding arms, fume ventilation systems ensure that the workspace remains free of contaminants and fumes that could lead to long-term health issues.

5. Budget Finally, budget considerations are crucial. While it’s important to invest in a quality extractor, it should also fit within the company's budget constraints.

Why Choose Yeed Tech Co., Ltd. for Your Fume Extraction Needs?

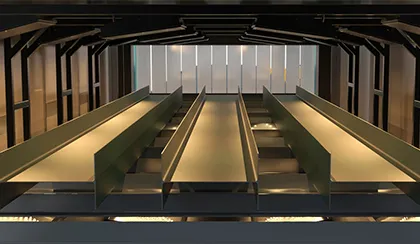

The versatility of builders steel is illustrated in its numerous applications. In residential construction, it is utilized in the framing of homes and in the fabrication of stairs, railings, and roofing systems. Commercial buildings take advantage of builders steel in foundations, floors, and support beams, allowing for expansive open spaces without compromising structural integrity.

In summary, automated spray coating systems stand at the forefront of industrial advancement, providing unmatched precision, efficiency, and reliability. Their rising prominence in the manufacturing sector underscores their value as both a technological marvel and a practical enhancement to production processes. As technology continues to evolve, these systems will undoubtedly play an even greater role in defining the future of manufacturing.

- 4. Adaptability Different designs are available for various types of cargo, making it easier to adapt to the specific needs of an operation.

In addition to improving efficiency and quality, automatic spray painting machines contribute to sustainable manufacturing practices. These systems are designed to optimize material usage, reducing waste and minimizing environmental impact.

Comment area