- Top: 8Step on: 16

automatisches farbspritzgerät

People involved | Date:2025-08-14 07:47:58

Related articles

In addition to automated arms, tools like the portable welding fume extractor are crucial for maintaining air quality in manufacturing facilities. These compact systems are designed to efficiently remove fumes and particulates from localized welding areas, making them ideal for workshops or smaller operations.

- Multiple Entry Points The design can easily accommodate multiple entry points, increasing convenience and traffic flow.

Conclusion

- Enhanced Productivity Cleaner air quality can lead to fewer health-related absences among workers, fostering a more efficient and productive work environment.

The Future of Automatic Spray Painting

4. Adequate Ventilation In addition to localized fume extraction systems, ensure that the overall workspace is well-ventilated. This helps to dilute the concentration of harmful substances in the air.

By combining mobile fume extractors with automated welding arms, manufacturers can ensure that every section of their operation benefits from both high-quality welding and a safe work environment. These mobile extractors can follow the welding process, adapting to different locations and needs without compromising on the extraction of harmful emissions.

3. Top Loaders As their name suggests, these machines lift containers from the top and are often used for stacking. They have a lower lifting capacity than other handlers but are useful for specific applications where bottom access is restricted.

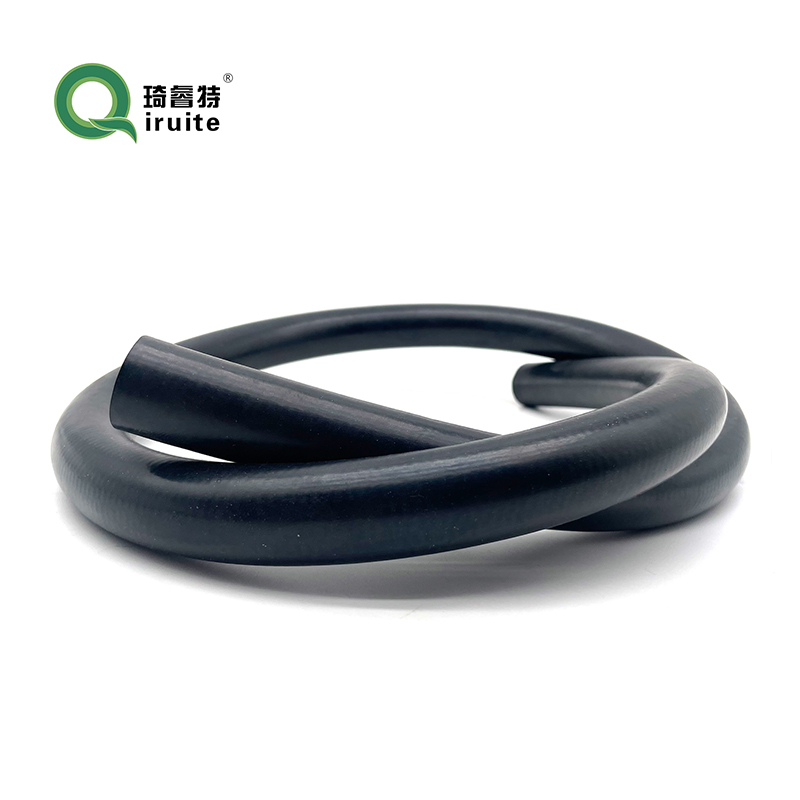

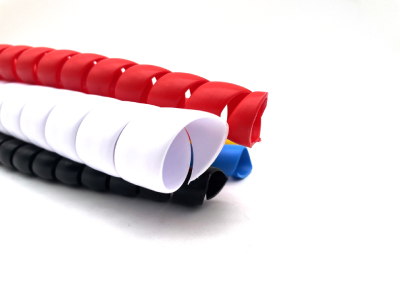

It is also important to ensure that the brake line is properly installed and secured to prevent it from coming loose during operation It is also important to ensure that the brake line is properly installed and secured to prevent it from coming loose during operation

It is also important to ensure that the brake line is properly installed and secured to prevent it from coming loose during operation It is also important to ensure that the brake line is properly installed and secured to prevent it from coming loose during operation

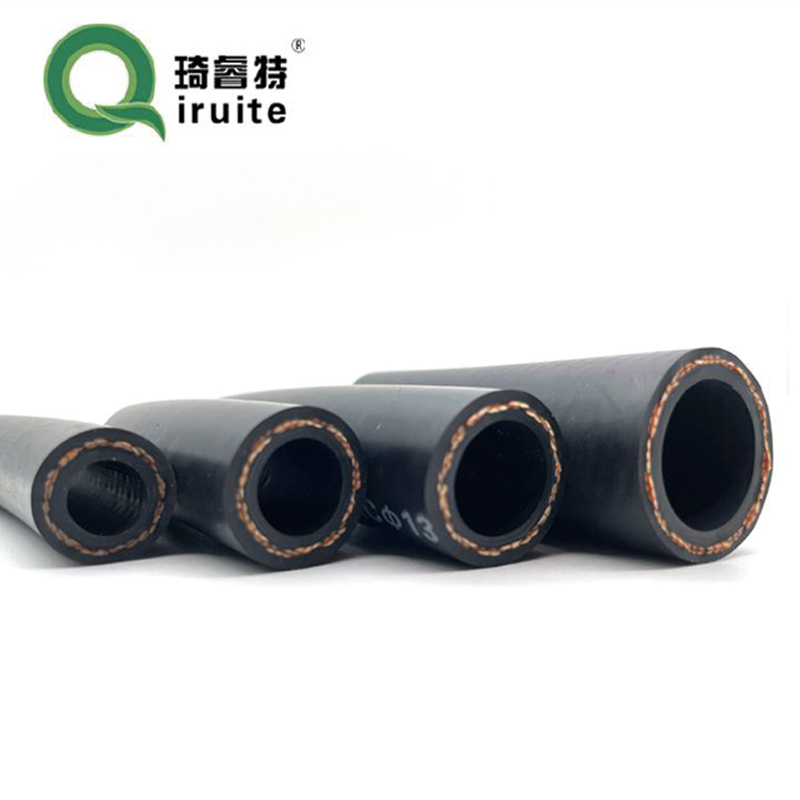

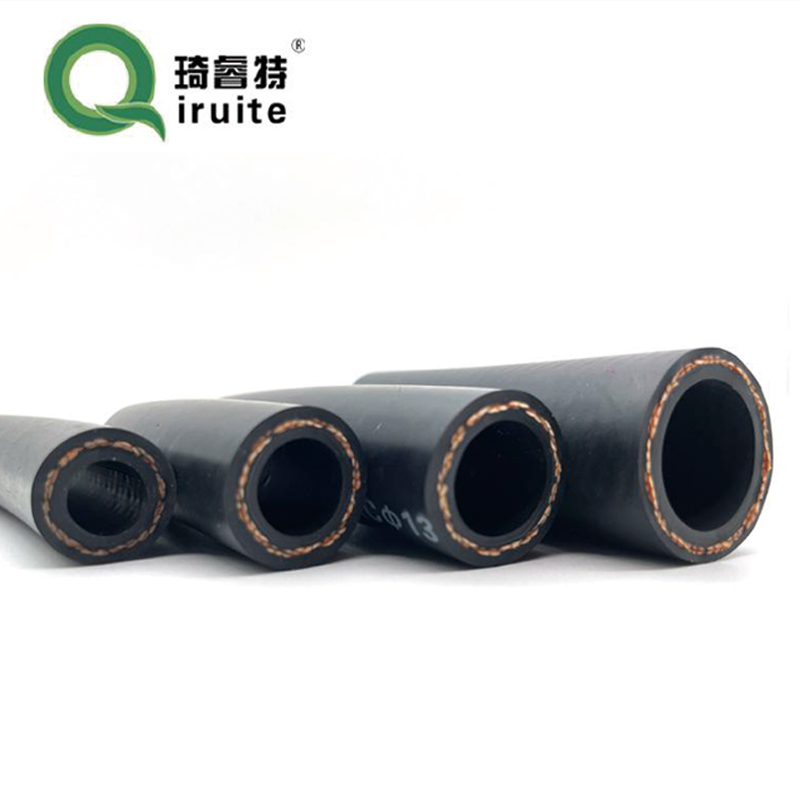

They are also available in various sizes, pressures, and temperature ratings, catering to the specific needs of different industries They are also available in various sizes, pressures, and temperature ratings, catering to the specific needs of different industries

They are also available in various sizes, pressures, and temperature ratings, catering to the specific needs of different industries They are also available in various sizes, pressures, and temperature ratings, catering to the specific needs of different industries

Regular Inspection It is essential to inspect the Gates 1-inch power steering hose regularly for any signs of damage, such as cracks, leaks, or swelling Regular Inspection It is essential to inspect the Gates 1-inch power steering hose regularly for any signs of damage, such as cracks, leaks, or swelling

Regular Inspection It is essential to inspect the Gates 1-inch power steering hose regularly for any signs of damage, such as cracks, leaks, or swelling Regular Inspection It is essential to inspect the Gates 1-inch power steering hose regularly for any signs of damage, such as cracks, leaks, or swelling

Comment area