- Top: 35Step on: 45452

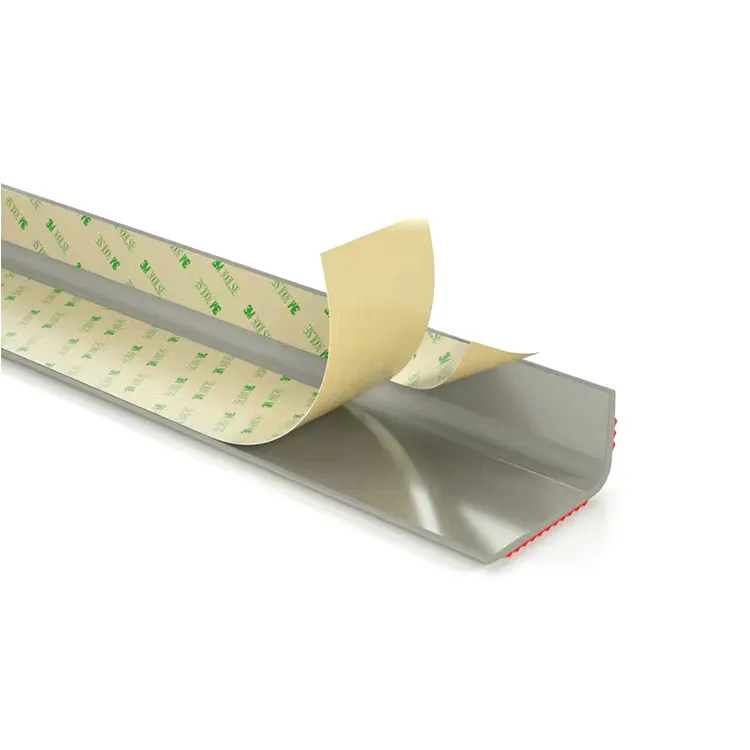

metal h stakes

People involved | Date:2025-08-15 00:30:08

Related articles

Maintaining Safety and Efficiency with Portable Fume Extraction Systems

Why Automatic Spray Painting Machines Are the Future

Conclusion

Welding generates a variety of hazardous emissions, including metal fumes, gases, and toxic substances. These emissions can include manganese, lead, and nickel, along with various welding fluxes that produce hazardous vapors. Prolonged exposure to these fumes can lead to serious health issues, including respiratory problems, neurological disorders, and even cancer. Consequently, effective ventilation and fume extraction systems are necessary to mitigate these risks and protect the health of welders.

The Last Container Lyft A Transformative Solution for Sustainable Logistics

Ưu Điểm Của Hệ Thống Sơn Tự Động

Expertise in operating these machines is paramount. Training programs are crucial to equip technicians and operators with the necessary skills to manage and maintain these sophisticated systems effectively. Such programs cover aspects such as programming the machines for different tasks, troubleshooting common issues, and performing routine maintenance to ensure optimal performance. As a result, a team equipped with expertise in automatic spray painting technology can vastly enhance the productivity and functionality of a manufacturing operation.

1. Regular Maintenance Ensure that fume extraction systems are regularly inspected and maintained to operate at peak efficiency. This includes cleaning filters, checking for blockages, and ensuring that fans and motors are functioning correctly.

Comment area