- Top: 85796Step on: 69791

projek mesin lukisan semburan automatik

People involved | Date:2025-08-14 05:29:39

Related articles

Don’t let outdated painting methods slow down your productivity. Embrace the future of painting technology with Yeed Tech Co., Ltd., where quality meets efficiency!

When paired with automated welding arms, wall mounted fume extractors provide consistent airflow and filtration across the workspace. The result is a high-performance welding environment where the automation process can run smoothly without any interruptions caused by environmental hazards. A proper fume extraction system is essential to achieving both high productivity and a clean, safe work environment.

- Bridges Given their strength and durability, steel floor systems are extensively used in bridge construction, supporting heavy vehicle traffic and ensuring longevity.

The integration of steel structure manufacturing equipment with automatic spray painting systems has transformed how manufacturers handle large-scale production. These machines provide consistent and even coatings, ensuring that every piece meets stringent quality standards.

- Stackers: Schedule efficient stacking of containers and save space in your facility.

Cats are often finicky drinkers. Many prefer running water over still water, which is a trait that stems from their ancestors who adapted to drink from streams and rivers, where the water is less likely to be contaminated. Dehydration in cats can lead to serious health issues, including urinary tract problems, kidney disease, and other complications. Therefore, providing a consistent and appealing source of water is crucial.

An automatic spray painting machine project is a tailored solution designed to improve efficiency and reduce manual labor in industrial coating applications. These machines automate the entire painting process, ensuring precision in every coat. Industries such as automotive, furniture, and construction rely on these systems to handle high-volume production without compromising quality.

To summarize, the integration of automated spray coating systems into manufacturing processes represents a significant step forward for industries prioritizing quality, efficiency, and environmental responsibility. By embodying cutting-edge technology, these systems deliver a compelling return on investment, transforming the landscape of production operations. Manufacturers investing in these systems not only gain a competitive edge but also endorse a commitment to precision, cost savings, and eco-friendly practices. As the industry continues to advance, the adoption of automated solutions will undoubtedly play a pivotal role in shaping the future of manufacturing.

Applications of Górny Podnośnik

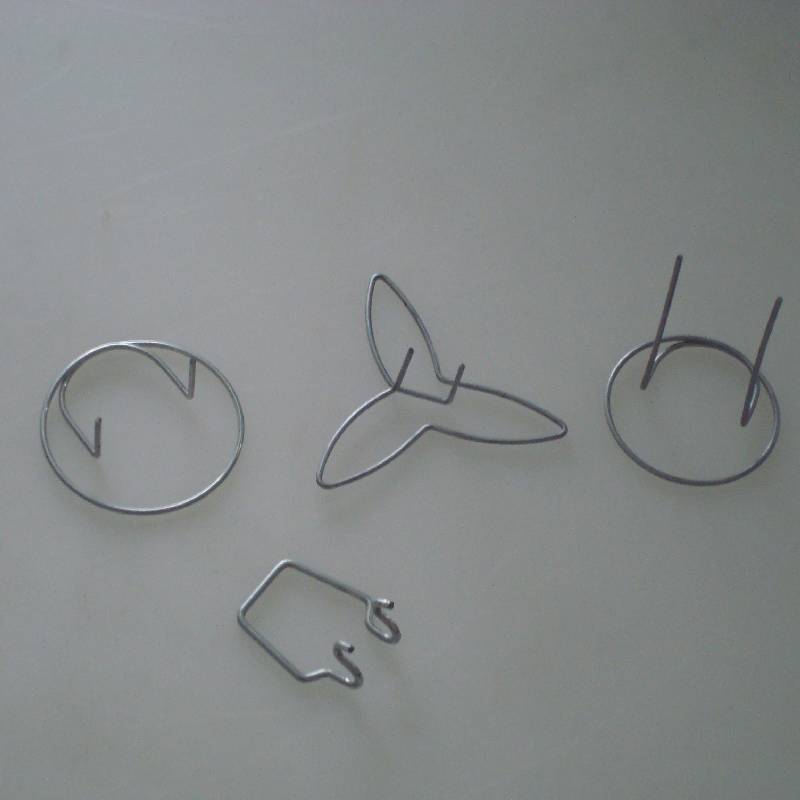

Wholesale distributors cater to the diverse needs of these sectors by offering a wide range of wire gauges and types, including galvanized, stainless steel, and high-carbon wire Wholesale distributors cater to the diverse needs of these sectors by offering a wide range of wire gauges and types, including galvanized, stainless steel, and high-carbon wire

Wholesale distributors cater to the diverse needs of these sectors by offering a wide range of wire gauges and types, including galvanized, stainless steel, and high-carbon wire Wholesale distributors cater to the diverse needs of these sectors by offering a wide range of wire gauges and types, including galvanized, stainless steel, and high-carbon wire Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them

Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them

Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit

Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit

Comment area